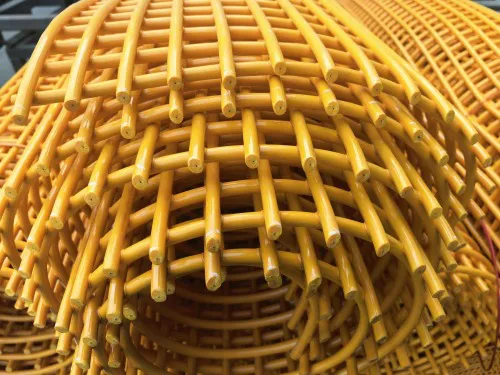

Polyurethane elastic screens are high-performance industrial screening elements made from polyurethane (PU) with embedded steel cable or polyester mesh. They are primarily used for material grading, dehydration, and de-mediation processes in mining, metallurgy, coal, and building materials industries.

Its core value lies in combining the excellent elasticity of polyurethane material with the tensile strength of steel wire.

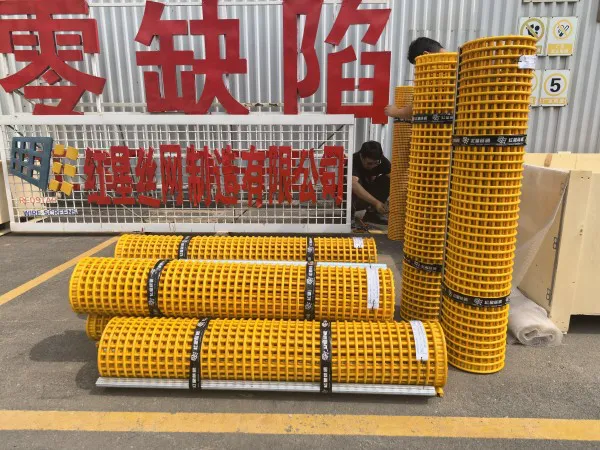

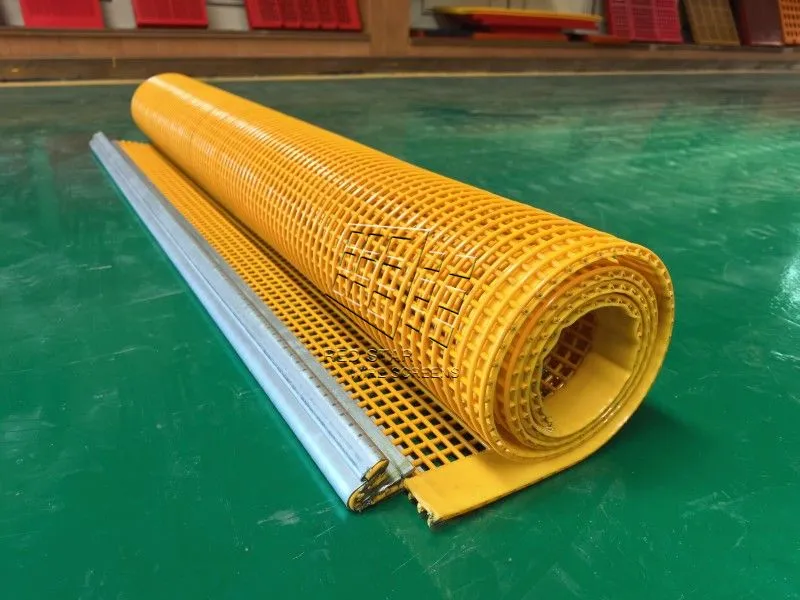

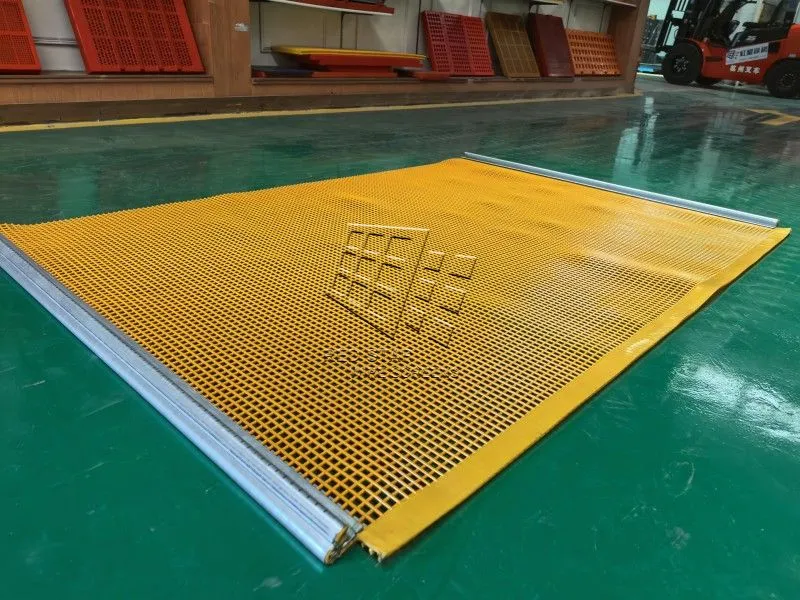

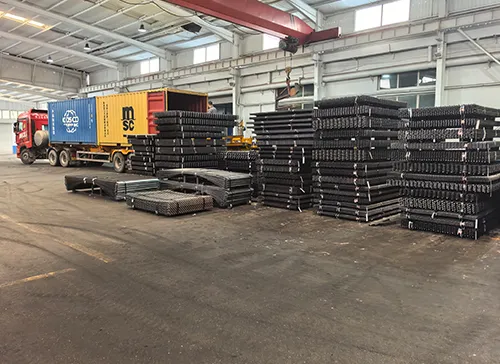

A

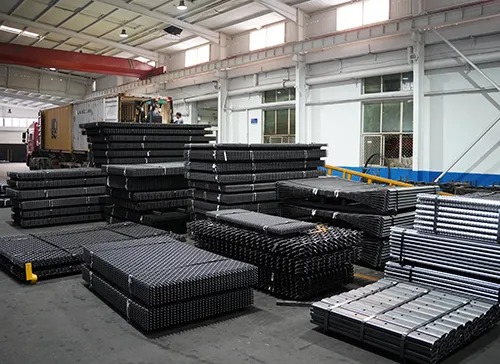

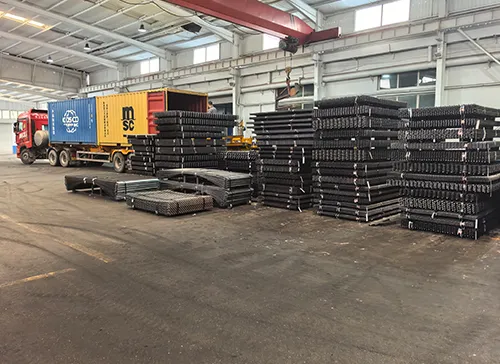

B

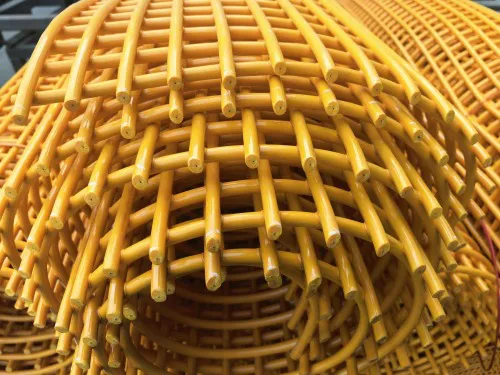

Polyurethane elastic screen is made of steel wire rope core covered with polyurethane layer as warp and weft wire, which is processed by heat fusion welding at a certain temperature.

Polyurethane elastic screen is made of steel wire rope core covered with polyurethane layer as warp and weft wire, which is processed by heat fusion welding at a certain temperature.

The service life of polyurethane elastic screen is 3-6 times that of ordinary metal screen, 3 times that of stainless steel screen and 3.5 times that of rubber screen.

The opening ratio of polyurethane elastic screen can reach more than 80%, and the permeability ratio can reach 95%.

It is suitable for ore, coal, metallurgy, building materials, electric power, water conservancy, chemical industry, etc. It has obvious advantages in sorting and processing lumpy and small and medium granular materials.

Sieve aperture range: 0.7mm-60mm

Wire diameter range: 1.5mm-14mm

Maximum size: 2.8m*5m

| Square Mesh Screen | |||

| Opening(mm) | Rope Diamond(mm) | Open Area | Type |

| 1.5 | 1.5 | 25% | F |

| 2.5 | 1.5 | 39% | F、P |

| 3 | 1.5 | 44% | F、P |

| 3 | 2 | 36% | F |

| 3 | 3 | 25% | P |

| 3.5 | 1.5 | 49% | F、P |

| 3.5 | 2 | 40% | F、P |

| 4 | 1.5 | 53% | F、P |

| 4 | 2 | 44% | F、P |

| 4 | 3 | 33% | F、P |

| 4.5 | 2 | 48% | F、P |

| 4.5 | 2.5 | 41% | F、P |

| 4.5 | 3 | 36% | F |

| 5 | 2 | 51% | F |

| 5 | 2.5 | 44% | F、P |

| 5 | 3 | 39% | F、P |

| 5.5 | 2.5 | 47% | F、P |

| 5.5 | 3 | 42% | F、P |

| 6 | 2.5 | 50% | F、P |

| 6 | 3 | 44% | F、P |

| 6 | 4 | 36% | F、P |

| 6.5 | 3 | 47% | F、P |

| 7 | 2.5 | 54% | F |

| 7 | 3 | 49% | F、P |

| 7 | 4 | 40% | F |

| 8 | 3 | 53% | F |

| 8 | 4 | 44% | F、P |

| 9 | 4 | 48% | F |

| 10 | 3 | 59% | F |

| 10 | 4 | 51% | F |

| 10 | 5 | 44% | F |

| 11 | 5 | 47% | F |

| 12 | 5 | 50% | F |

| 13 | 5 | 52% | F |

| 13 | 6 | 47% | F |

| 14 | 5 | 54% | F |

| 14 | 7 | 44% | F |

| 14 | 8 | 40% | F |

| 15 | 5 | 56% | F |

| 15 | 6 | 51% | F |

| 15 | 7 | 46% | F |

| 16 | 5 | 58% | F |

| 16 | 6 | 53% | F |

| 16 | 8 | 44% | F |

| 17 | 6 | 55% | F |

| 17 | 7 | 50% | F |

| 18 | 6 | 56% | F |

| 20 | 6 | 59% | F |

| 20 | 7 | 55% | F |

| 20 | 8 | 51% | F |

| 20 | 10 | 44% | F |

| 21 | 6 | 60% | F |

| 21 | 7 | 56% | F |

| 21 | 8 | 52% | F |

| 21 | 10 | 46% | F |

| 22 | 6 | 62% | F |

| 22 | 7 | 58% | F |

| 22 | 8 | 54% | F |

| 22 | 10 | 47% | F |

| 23 | 6 | 63% | F |

| 23 | 8 | 55% | F |

| 23 | 10 | 49% | F |

| 23 | 12 | 43% | F |

| 24 | 6 | 64% | F |

| 24 | 10 | 50% | F |

| 25 | 8 | 57% | F |

| 25 | 10 | 51% | F |

| 26 | 10 | 52% | F |

| 26 | 12 | 47% | F |

| 27 | 10 | 53% | F |

| 27 | 12 | 48% | F |

| 28 | 8 | 60% | F |

| 28 | 10 | 54% | F |

| 30 | 12 | 51% | F |

| 32 | 12 | 53% | F |

| 35 | 12 | 55% | F |

| 38 | 12 | 58% | F |

| 40 | 12 | 59% | F |

| 43 | 12 | 61% | F |

| 44 | 12 | 62% | F |

| 45 | 12 | 62% | F |

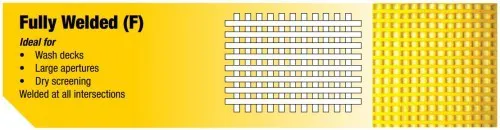

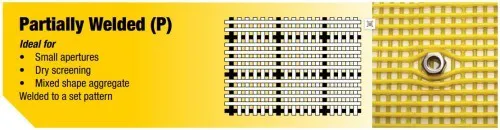

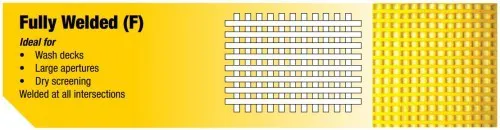

F= Fully Welded Apertures

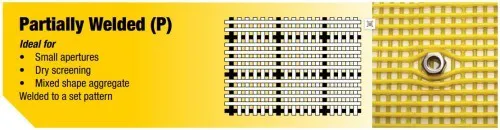

P= Partially Welded Apertures

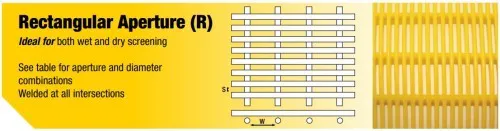

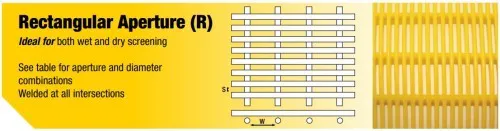

| Rectangular mesh screen | ||||

| Opening(mm) | Rope Diamond(mm) | Open Area | ||

| S | W | Synthetic | S/S Wire | |

| 0.7 | 15 | 3 | 6 | 14% |

| 1 | 15 | 3 | 6 | 18% |

| 1.5 | 15 | 3 | 6 | 24% |

| 2 | 18 | 1.5 | 3 | 49% |

| 2 | 18 | 2 | 4 | 41% |

| 2.5 | 10 | 1.5 | 3 | 48% |

| 2.5 | 10 | 2 | 6 | 35% |

| 2.5 | 18 | 2 | 4 | 45% |

| 2.7 | 16 | 2 | 6 | 43% |

| 3 | 18 | 3 | 4 | 41% |

| 3.5 | 13 | 2 | 3 | 52% |

| 4 | 16 | 3 | 5 | 44% |

| 4.5 | 18 | 2.5 | 4 | 53% |

| 5 | 20 | 4 | 6 | 43% |

| 6 | 13 | 2.5 | 3 | 57% |

| 7 | 21 | 3 | 3 | 61% |

(1) High elasticity: The elasticity of polyurethane is 3-8 times that of natural rubber. It can rebound quickly under the impact of ore and reduce clogging (opening rate increased by 15-30%).

(2) Wear resistance and tear resistance : The wear resistance is 3-5 times that of steel plates, and the service life is 8-10 times that of metal screens (for example, it can reach 12-24 months in coal washing plants).

(3) Corrosion resistance: Resistant to acid/alkaline media (pH 3-12), oil and water erosion, suitable for wet screening.

(4) Noise reduction and vibration reduction: It reduces noise by 10-15 decibels compared to metal screens, improving the working environment.

(1) Reinforced skeleton: usually embedded with steel cable or polyester mesh to provide tensile strength (can withstand tension >50kN/m).

(2) Edge sealing technology: The edge of the screen is sealed with metal edge plates or polyurethane casting to ensure that it will not deform during tensioning installation.

(3) Opening form: square, rectangular, etc., aperture 0.1mm-150mm can be customized (0.1-3mm is commonly used for fine particle classification, and 10-100mm is mostly used for aggregate screening ).

| index | Polyurethane elastic screen | Metal screen | Rubber screen |

| Service life | 8-24 months | 1-3 months | 6-12 months |

| Opening rate | 35%-50% | 25%-40% | 30%-45% |

| Plugging rate | <5% (self-cleaning effect) | 15%-30% | 10%-20% |

| Noise level | 70-80 dB(A) | 85-100 dB(A) | 75-85 dB(A) |

| Impact resistance | ★★★★★ (Absorbed kinetic energy>50J) | ★★★★☆ (Easily deformed) | ★★★★★ |

The advantage of elasticity is reflected in: the screen surface is slightly deformed when the ore impacts → elastic force is released → material is thrown + hole wall self-cleaning → efficiency is increased by 20%-40%.

(1) High wear conditions

Iron ore/gold ore primary screening: Resistant to impact wear of ores >50mm (lifespan up to 18 months).

Quartz sand classification: resistant to fine-grain abrasion (0.2-1mm aperture screen annual wear <1mm).

(2) Wet screening

Coal washing plant dehydration and desludging: elastic vibration accelerates the stripping of water molecules (moisture content reduced by 3%-5%).

Aggregate water washing screen: anti-mud corrosion (no aging in pH 4-10 environment).

(3) Fine grading

Calcium carbonate micropowder sieve (200 mesh): 0.075mm aperture maintains long-term stability.

Recycled plastic sorting: elastic surface reduces fiber entanglement.

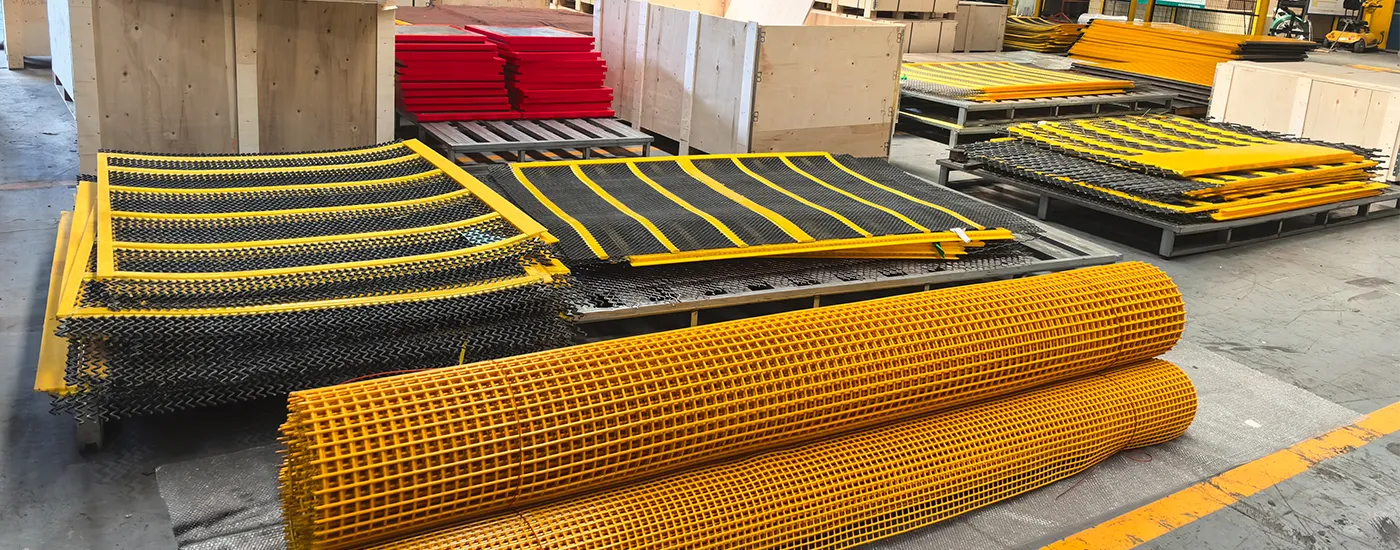

1. Classification by structure

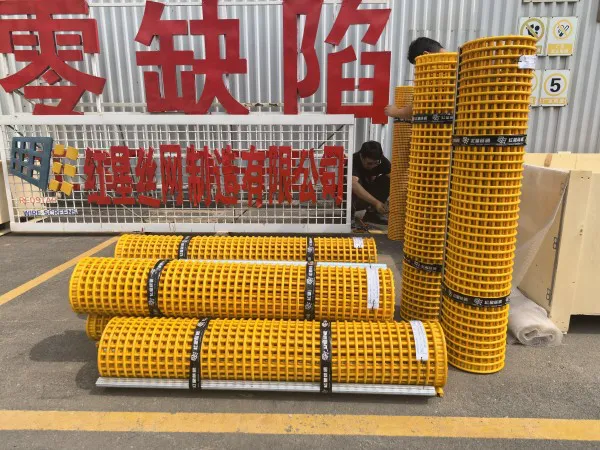

Tensioned Type: Steel wire rope core + metal edging, suitable for large vibrating screens (such as Derrick high-frequency screens).

Modular Type: A quick-install design with bolt holes, which increases replacement efficiency by 70% (such as Schenck Process's POLY-MOD series).

2. Select by function

| need | Recommended Type | Case |

| Resistant to large impacts | Thick PU + multi-layer steel wire rope (≥25mm) | Granite crushing primary screen |

| Fine grading | Thin layer of PU + polyester mesh (8-15mm) | Silica powder ultrasonic sieve |

| High dehydration rate | Slit screen (slit width 0.5-3mm) | Coal preparation plant uncoal dewatering screen |

Red Star recommends: When selecting a model, it is necessary to comprehensively consider material characteristics, equipment parameters and cost cycle in order to maximize its technical value.

(1) Tension control: A uniform tension of 15-20 kN/m must be maintained (too loose will cause breakage, too tight will accelerate hemming fatigue).

(2) Temperature limit: long-term working temperature -30℃~+80℃ (elasticity drops sharply when >100℃).

(3) Avoid contact: Strong oxidants (such as concentrated nitric acid) and ester solvents (such as ethyl acetate) will swell the material.

A

B

Our experienced staff is available to discuss your needs and to help determine which product is best for your particular application.

Request a quote or call us at +86 187 3080 2171

Red Star Wire Mesh Manufacturing Co., Ltd. is not an authorized repair facility nor does it have an affiliation with the original equipment manufacturers (OEM) listed above. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval of Red Star Wire Mesh Manufacturing Co., Ltd. , Inc. by the named OEM, respectively. All parts are manufactured by, for and warranted by Red Star Wire Mesh Manufacturing Co., Ltd. are not manufactured by, purchased from or warranted by the OEM.

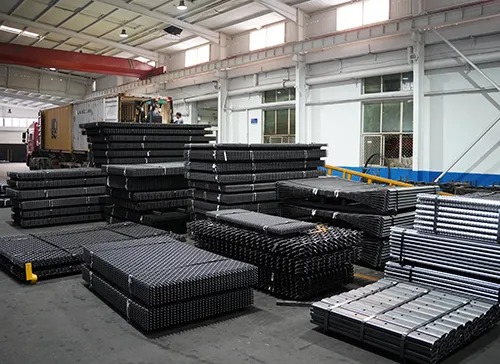

Factory Address:

1 Hongxing Rd, Anping County, Hengshui, Hebei, China

Email:

info@redstarfactory.com

WhatsApp :

+86 187 3080 2171

Phone:

+86 187 3080 2171

WeChat:

+86 187 3080 2171

Working Hours:

Monday – Friday: 8:00 AM – 5:00 PM (GMT+8). We reply to all inquiries within 12–24 hours, regardless of time zone.