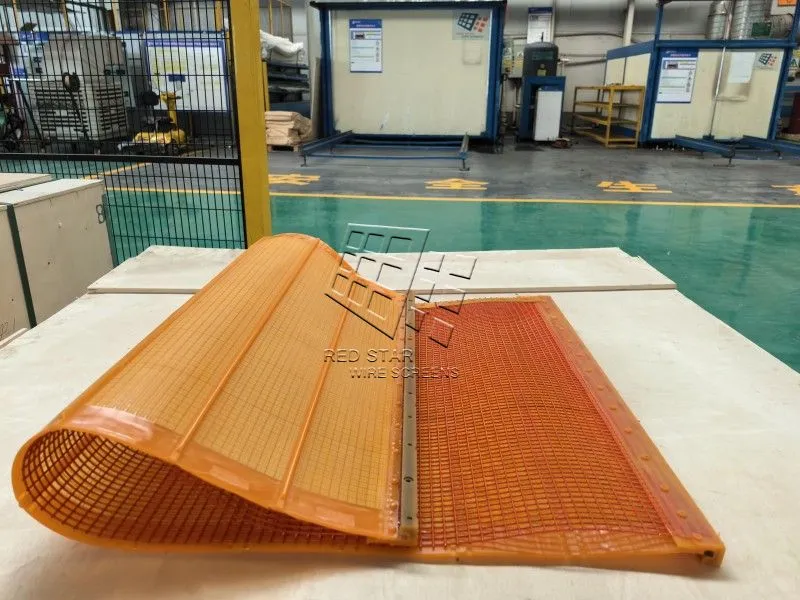

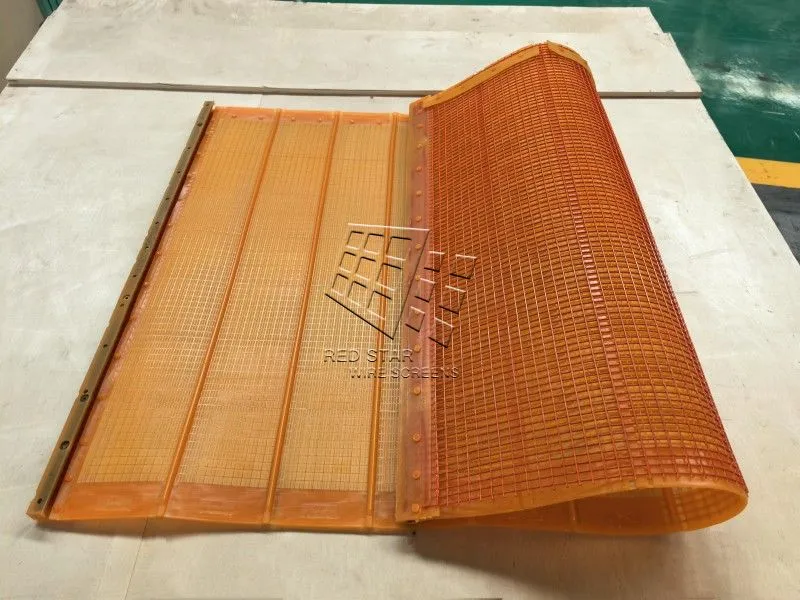

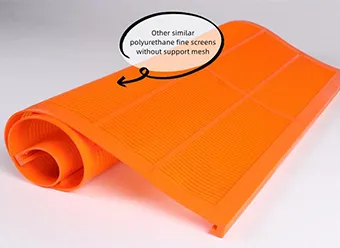

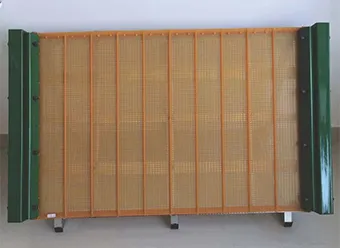

Fine PU Screens, also known as Polyurethane Fine Aperture Screen Panels, are high-precision screening media manufactured from high-performance polyurethane elastomer for critical fine material separation. Engineered for applications such as grading, dewatering, de-mediation, and desludging, they deliver precise screening of particles typically ranging from 0.1 mm to 3 mm. Widely used in mining, coal washing, and mineral processing, Fine PU Screens provide a durable, wear-resistant, and long-life alternative to traditional metal screen panels.

Screen Slot Range: 0.045 mm – 3 mm

Opening Rate: 15.25% – 46.51%

Material: High-performance polyurethane elastomer

Screen Type: Fine aperture / slot opening

Panel Thickness: Customized according to screening capacity

Installation System: Modular fastening, bolt-down, rail mounting

High-precision screening for fine and ultra-fine materials

Excellent abrasion and impact resistance

Stable performance in wet and slurry conditions

Lower noise level compared with metal wire screens

Consistent aperture accuracy for reliable grading

Extended service life, reducing downtime and replacement costs

Fine PU Screens are ideal for demanding fine screening applications, including:

Coal grading and coal washing plants

Slurry dewatering systems

Tailings treatment and recovery

Fine mineral classification

Desliming and desludging processes

Red Star Wire Mesh provides custom Fine PU Screens and OEM Polyurethane Fine Aperture Screen Panels to suit different vibrating screen models and operating capacities. Custom slot sizes, opening rates, panel dimensions, hardness levels, and fixing systems are available to ensure optimal screening efficiency for your application.

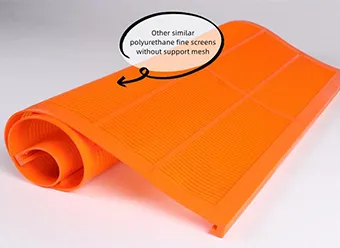

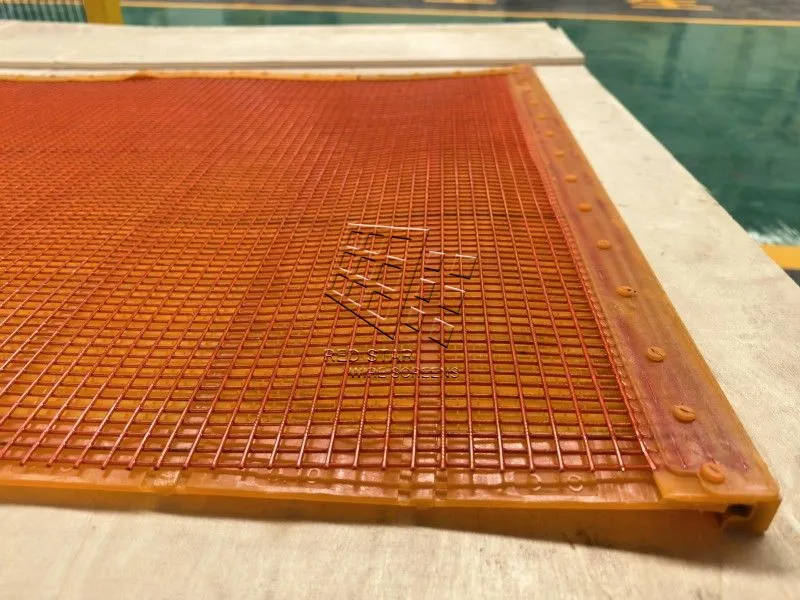

(1) Effectively protect the screen surface, avoid abnormal wear, and significantly extend the service life of the screen.

(2) Greatly enhance the bearing capacity of the screen, ensure that the screen gap is stable and does not deform, and stably screen the material.

(3) No need to regularly tighten the screen during use, reducing downtime and maintenance costs.

5. The screen material is 100% recyclable.

6. Customized production can be carried out according to customer requirements.

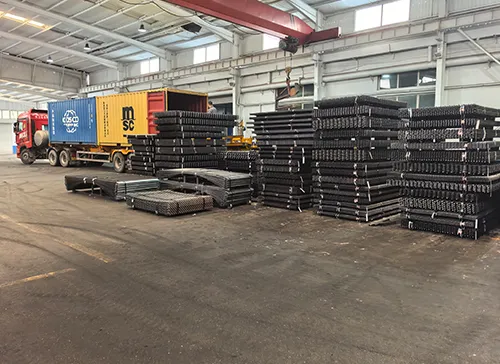

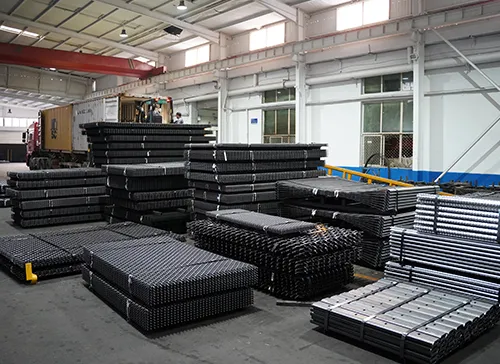

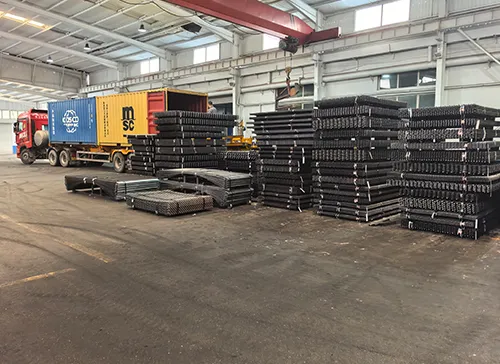

Red Star Wire Mesh Manufacturing Co., Ltd. is a globally trusted supplier with strong technical expertise and large-scale production capability in mining screen mesh manufacturing.

Established in 1989 with 36 years of industry experience

Factory area of 58,730 m² with dedicated polyurethane screen workshop

Five major workshops covering wire mesh and polymer screening products

More than 260 sets of advanced production and testing equipment

4000 m² R&D center for new wear-resistant materials

18 patented screening products

Drafting unit for China mining anti-blocking self-cleaning screen standards

ISO9001, ISO14001, ISO45001 certified manufacturer

Each Fine PU Screen Panel is manufactured under strict quality control, from polyurethane formulation and molding to final dimensional inspection. Advanced testing ensures accurate slot sizes, stable opening rates, and consistent performance in harsh fine screening environments.

Looking for a dependable Fine PU Screens manufacturer, supplier, or OEM partner? Contact Red Star Wire Mesh today for competitive pricing, fast delivery, and customized polyurethane fine screening solutions tailored to your project requirements.

Polyurethane fine screen is a screen designed for high-precision screening for fine particle separation and high-purity material processing.

Polyurethane fine screen is a screen designed for high-precision screening for fine particle separation and high-purity material processing.

Polyurethane fine sieve has an opening rate as high as 31%-42%, adopts integral one-shot molding technology and built-in fiber reinforcement, which is not easy to crack and improves the service life of the sieve mesh.

Widely used in coal, ore, chemical raw materials, grain and other fine classification, can simultaneously realize the function of dewatering and demetallization.

Sieve hole range: 0.075mm-3mm

| Screen Slot | Opening Rate |

| 0.045 | 15.25% |

| 0.053 | 17.50% |

| 0.063 | 22.00% |

| 0.075 | 28.30% |

| 0.1 | 32.10% |

| 0.125 | 30.60% |

| 0.15 | 33.98% |

| 0.18 | 37.38% |

| 0.2 | 39.64% |

| 0.25 | 35.00% |

| 0.3 | 39.60% |

| 0.35 | 40.00% |

| 0.7 | 46.20% |

| 0.8 | 43.44.% |

| 0.9 | 48.87% |

| 1 | 43.35% |

| 1.2 | 47.80% |

| 2 | 57.53% |

| 2.5 | 46.51% |

| 3 | 46.51% |

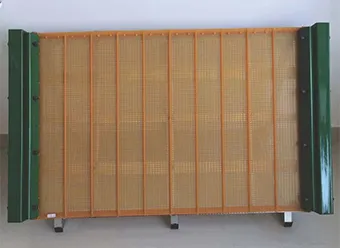

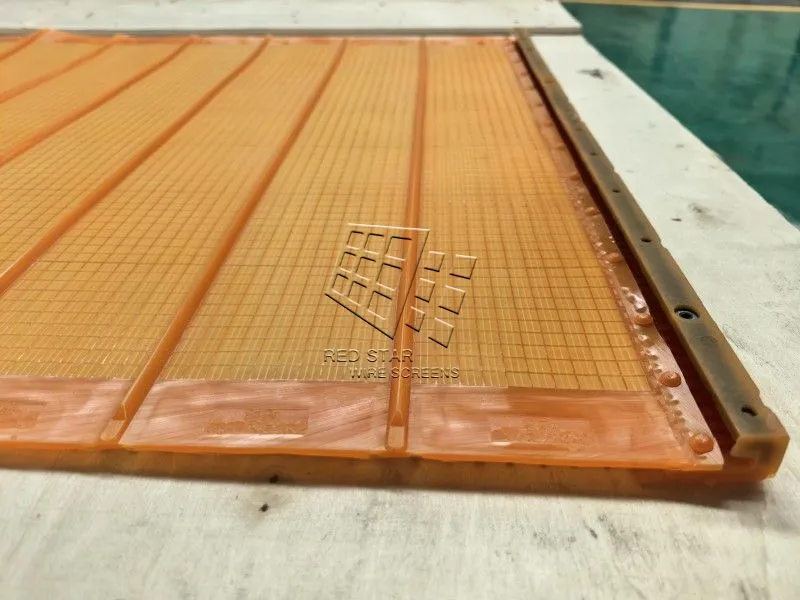

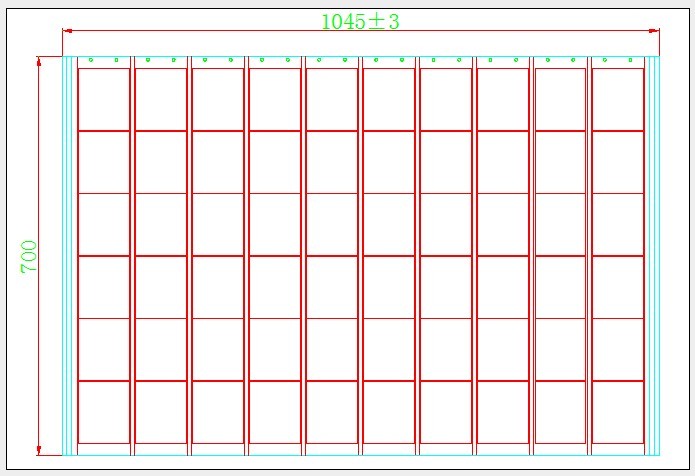

R-A Type: Common Specifications: 700*1045mm

Equipped with mounting hooks on both sides, located along the 700mm width, with the feed end oriented along the length.

Two Length Series:

1. Basic Length: 1045mm, which can be extended in increments of 100mm, for example: 1145mm, 1245mm, 1345mm, etc.

2. Basic Length: 1110mm (1120mm), which can be extended in increments of 100mm, for example: 1210mm (1220mm), 1310mm (1320mm), 1410mm (1420mm), etc.

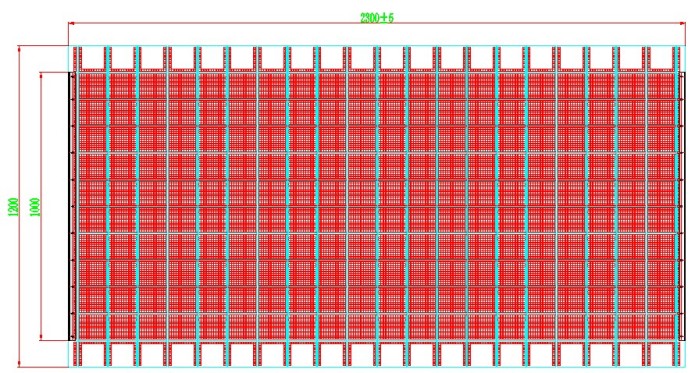

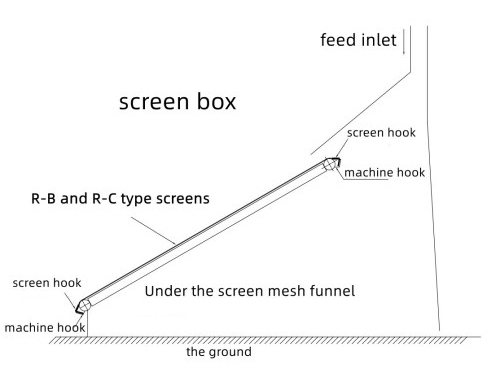

R-B Type: Common Specifications: 1000*2300mm

Width: 1200mm (1000mm mesh area, 100mm blind area at each end), with the hook located at the 1200mm end, with the feed end oriented at the 1200mm end.

The length starts at a basic length of 740mm and can be extended in increments of 111.5mm. For example: 851.5mm, 963mm, 1074.5mm, ... 2300mm, 2411.5mm, ...

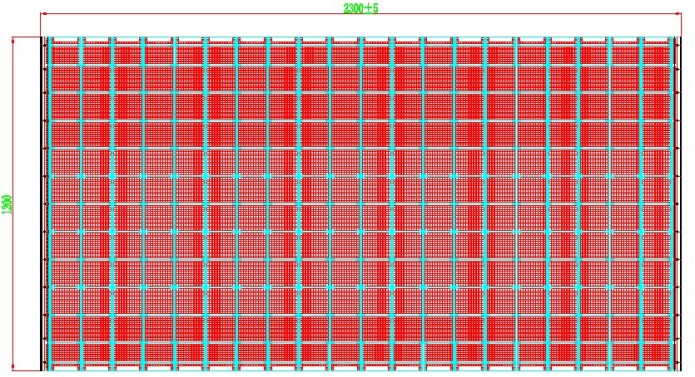

R-C Type: Common specifications: 1200*2300mm

The width is 1200mm (1140mm net area, 30mm blind area at each end). The hook is at the 1200mm end, and the 1200mm end is the feed end.

The length starts at a basic length of 740mm and can be extended in increments of 111.5mm. For example: 851.5mm, 963mm, 1074.5mm, ... 2300mm, 2411.5mm, ...

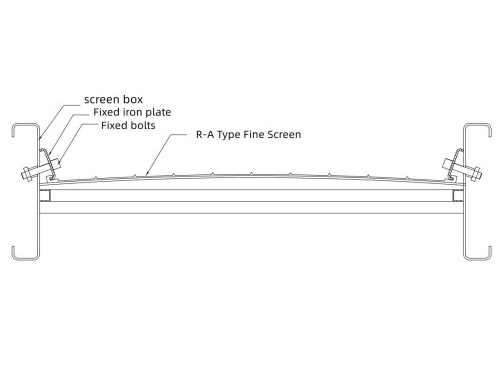

①Spread out the screen mesh

②The hooks of the fine screen are pulled tight and fixed to the iron plate of the screening machine.

③Tighten the bolts.

④Rubber pads or impact-resistant blind plates should be installed at the feed inlet to prevent materials from directly impacting the screen surface.

|  |  |

| 5-R-A Type Screen Installation Diagram | 6-R-B and R-C Type Screens Installation Diagram | 7-On-site screening machine installation |

(1) Effectively protect the screen surface, avoid abnormal wear, and significantly extend the service life of the screen.

(2) Greatly enhance the bearing capacity of the screen, ensure that the screen gap is stable and does not deform, and stably screen the material.

(3) No need to regularly tighten the screen during use, reducing downtime and maintenance costs.

5. The screen material is 100% recyclable.

6. Customized production can be carried out according to customer requirements.

Our experienced staff is available to discuss your needs and to help determine which product is best for your particular application.

Request a quote or call us at +86 187 3080 2171

Red Star Wire Mesh Manufacturing Co., Ltd. is not an authorized repair facility nor does it have an affiliation with the original equipment manufacturers (OEM) listed above. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval of Red Star Wire Mesh Manufacturing Co., Ltd. , Inc. by the named OEM, respectively. All parts are manufactured by, for and warranted by Red Star Wire Mesh Manufacturing Co., Ltd. are not manufactured by, purchased from or warranted by the OEM.

Factory Address:

1 Hongxing Rd, Anping County, Hengshui, Hebei, China

Email:

info@redstarfactory.com

WhatsApp :

+86 187 3080 2171

Phone:

+86 187 3080 2171

WeChat:

+86 187 3080 2171

Working Hours:

Monday – Friday: 8:00 AM – 5:00 PM (GMT+8). We reply to all inquiries within 12–24 hours, regardless of time zone.