Overview – What Are Piano Wire Screens?

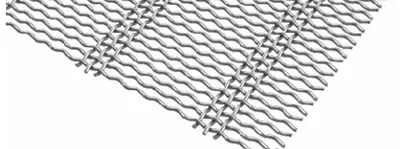

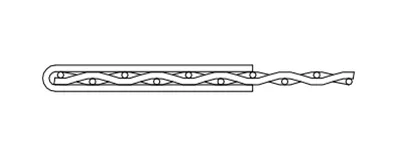

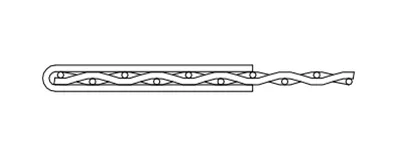

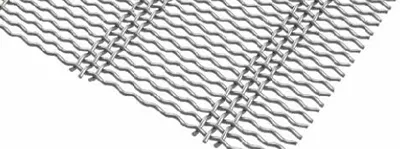

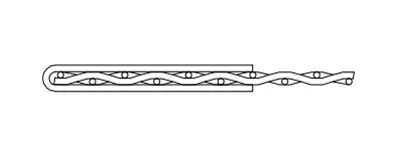

① Piano wire screens—also known as high-tensile self-cleaning screens or harp wire screens —are engineered for applications where traditional woven wire mesh struggles with blinding, pegging, and clogging.

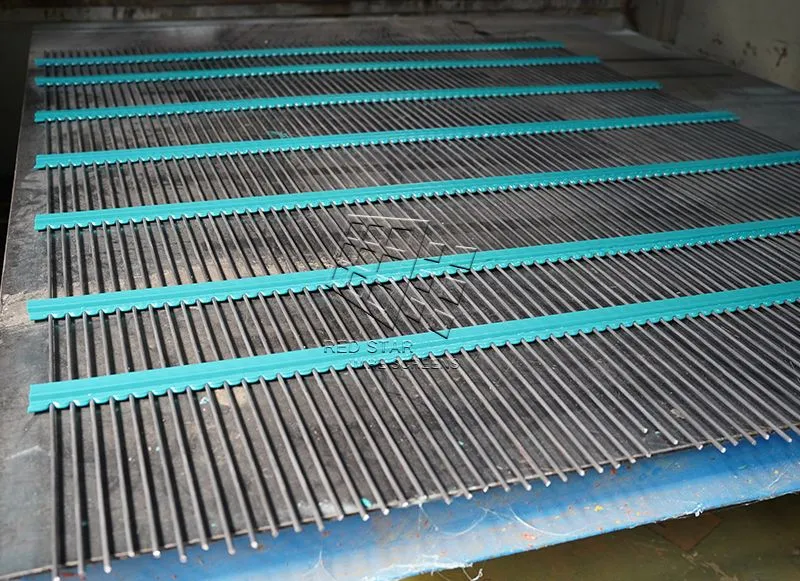

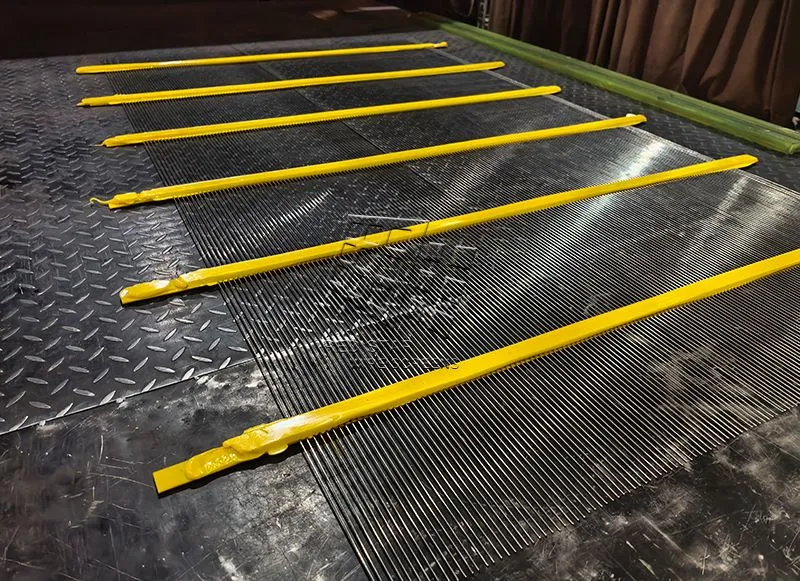

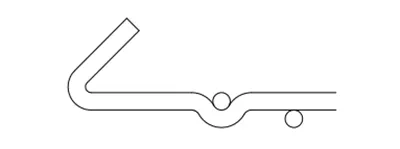

② These screens use parallel high-tensile steel wires supported by polyurethane or steel cross members, allowing the wires to vibrate independently to release fines and prevent material from getting stuck.

③ Compared with standard woven screens, piano wire screens deliver significantly higher open area, consistent stratification, and improved screening efficiency in wet, sticky, or fine materials.

Applications of Piano Wire Screens

Piano wire screens are widely used in the mining, aggregates, construction, recycling, and general industrial sectors, delivering excellent performance for screening wet, sticky, fine, or hard-to-process materials.

Technical Specifications of Piano Wire Screens

Wire material: 65Mn, High-Carbon Steel, Spring Steel, 304 Stainless Steel

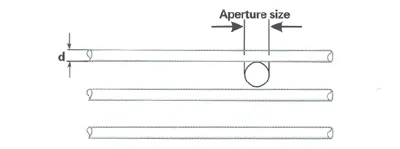

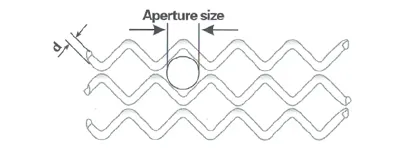

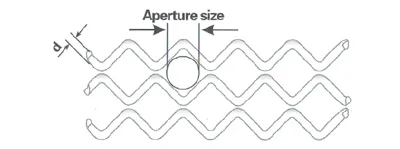

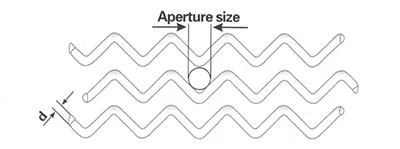

Wire diameter: 0.5–6.0 mm (custom available)

Aperture range: 1.0–50 mm

Width: Up to 2500 mm

Length: Custom per deck size

Cross support: Polyurethane strips, Rubber strips, or Steel hooks

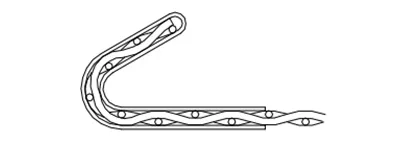

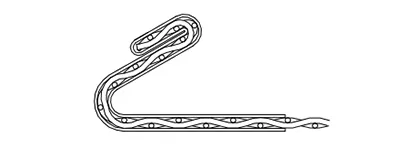

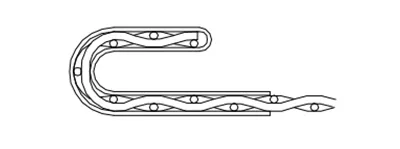

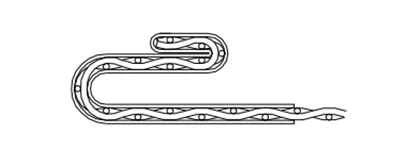

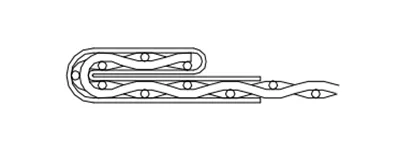

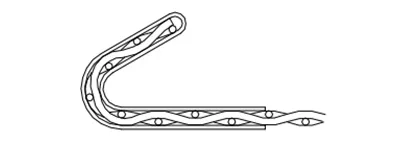

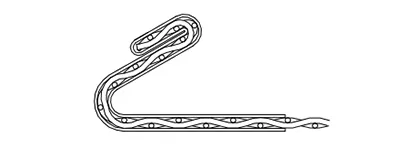

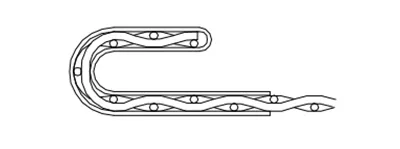

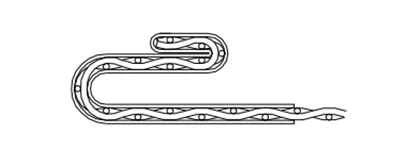

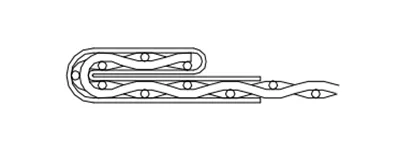

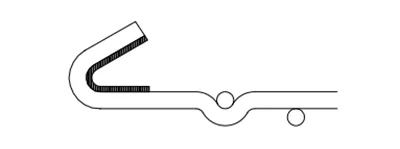

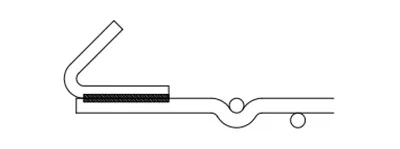

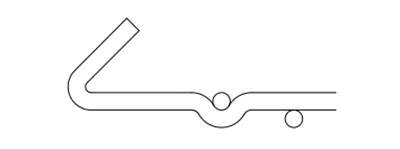

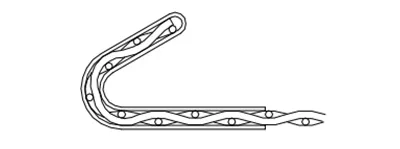

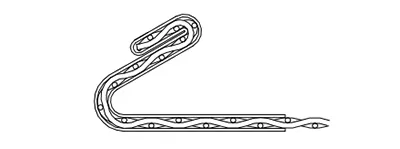

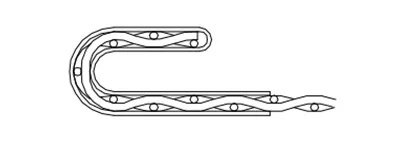

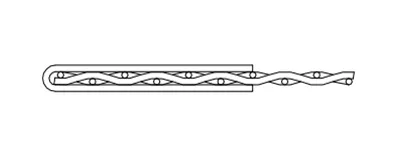

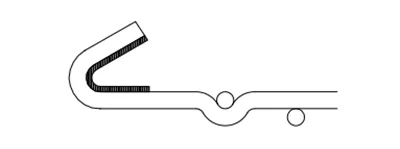

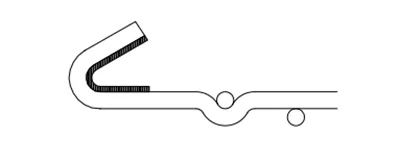

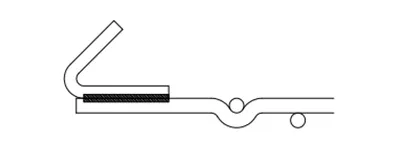

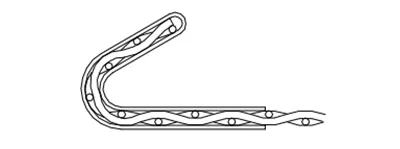

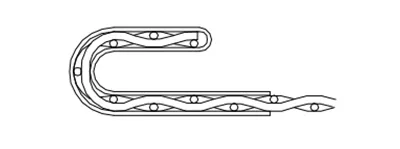

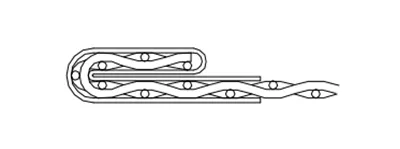

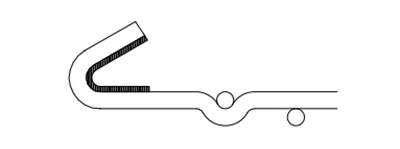

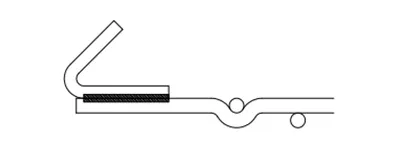

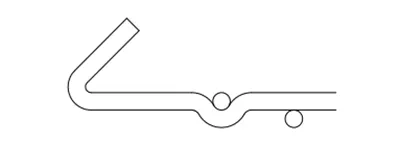

Hook types: C-Type, U-Type, 45° / 180° hooks, or custom tension hooks

Red Star's piano wire screens are designed to fit and perform reliably on vibrating screens from top brands, including Metso, Sandvik, Terex, Powerscreen, McCloskey, and Astec.

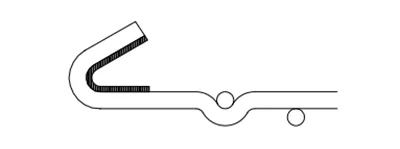

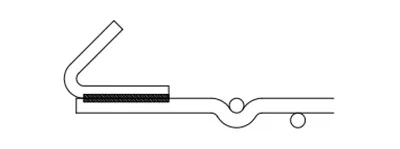

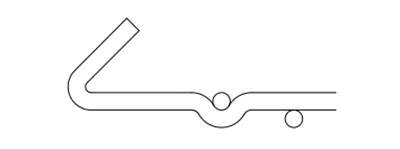

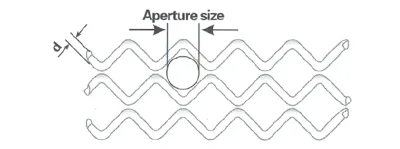

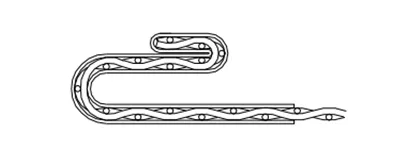

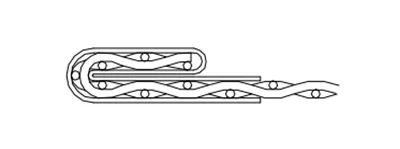

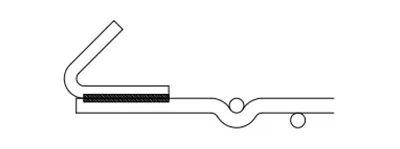

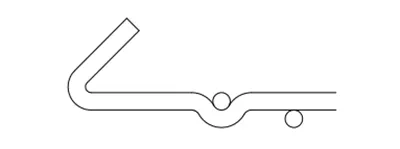

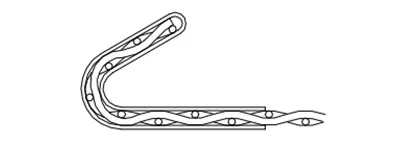

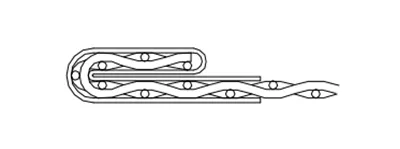

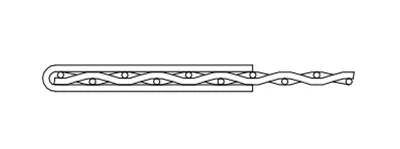

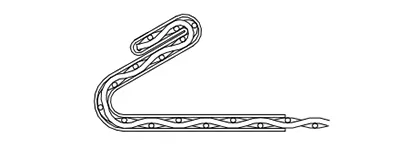

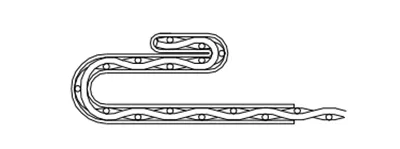

Type A

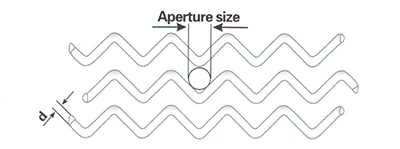

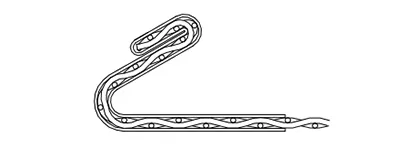

Type B

Type C

Type D

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

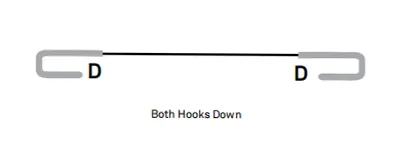

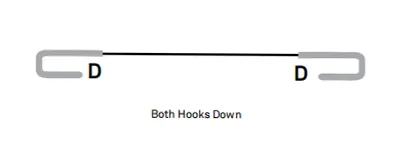

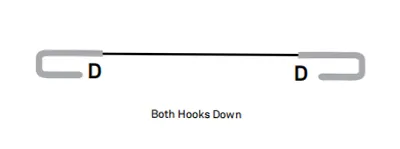

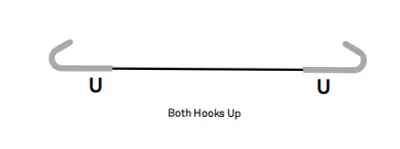

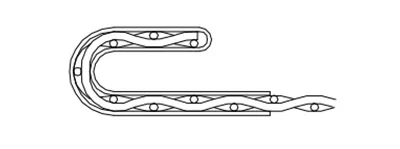

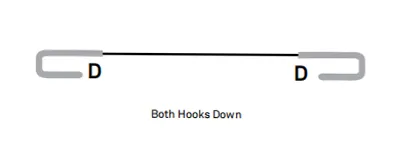

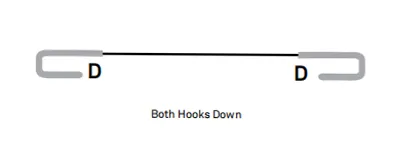

Both Hooks Down

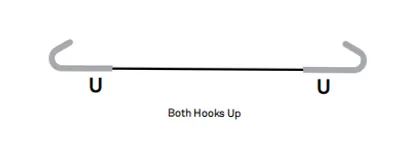

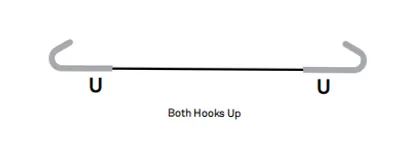

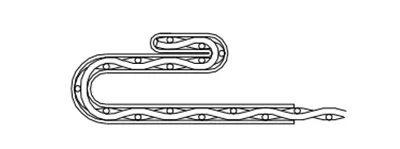

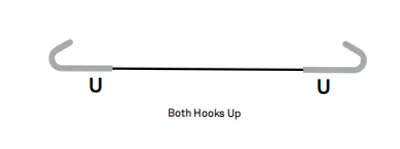

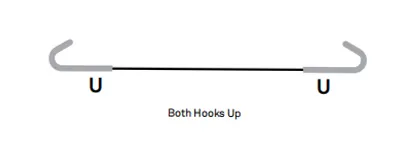

Both Hooks Up

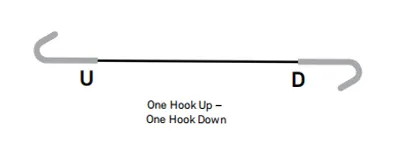

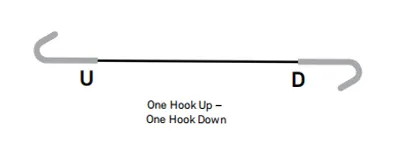

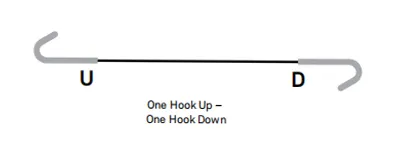

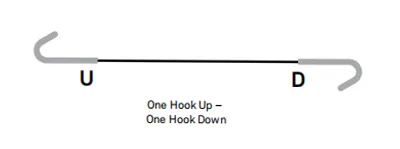

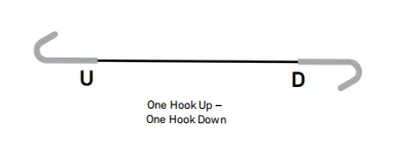

One Hook Up and One Hook Down

High screening efficiency due to uniform wire tension

Excellent resistance to abrasion and impact

Reduced material clogging and blinding

Stable vibration transfer for higher processing capacity

Extended service life, reducing replacement frequency

Red Star Wire Mesh offers custom piano wire screens and OEM manufacturing services to meet specific equipment and operating requirements. Whether you need special aperture sizes, non-standard panel dimensions, or tailored wire materials, our engineering team can deliver precise and reliable solutions.

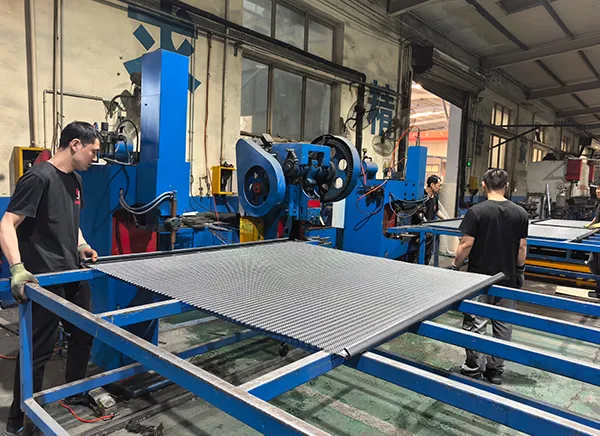

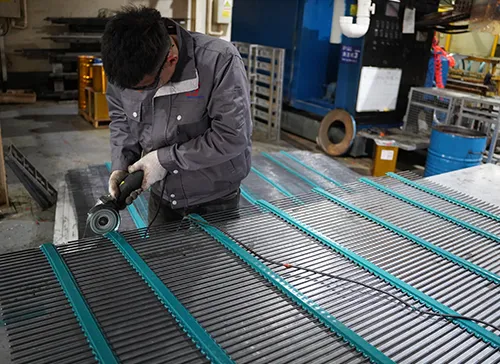

Screen weaving

Screen cutting

Screen Forming

Screen Inspection

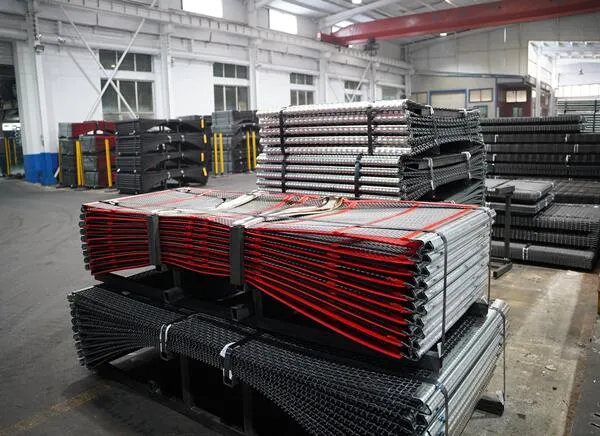

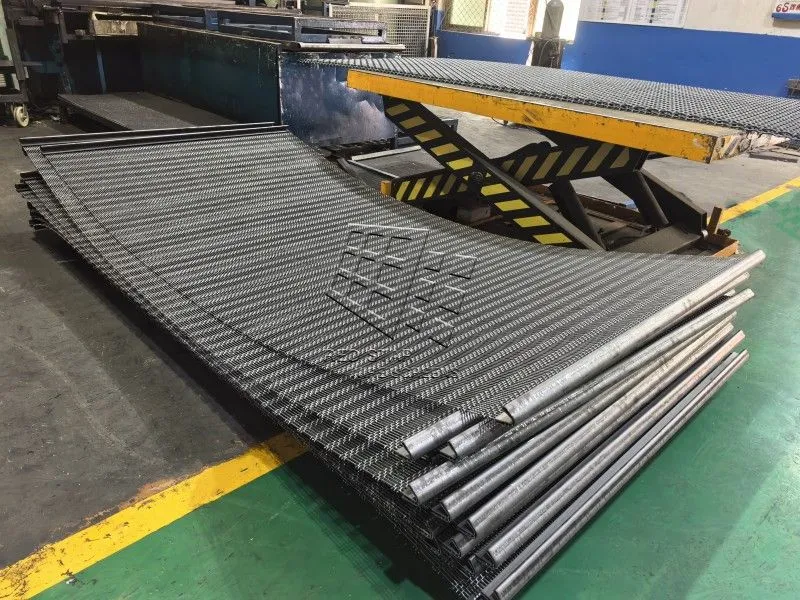

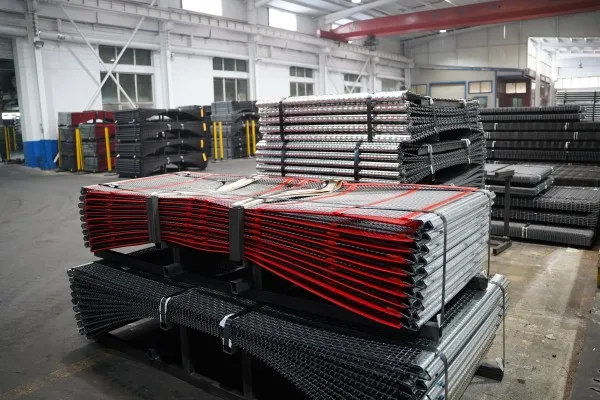

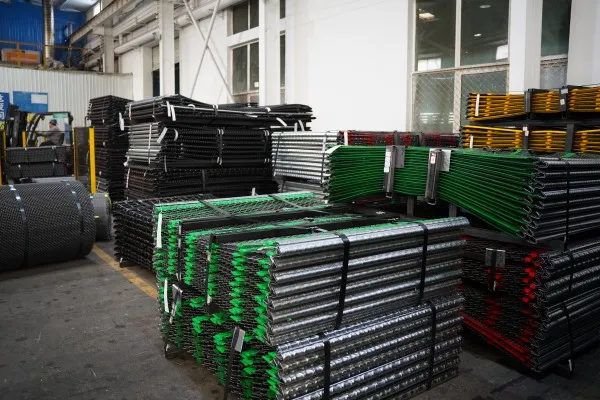

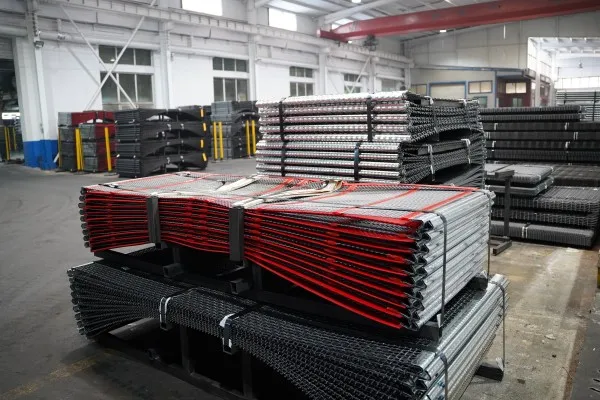

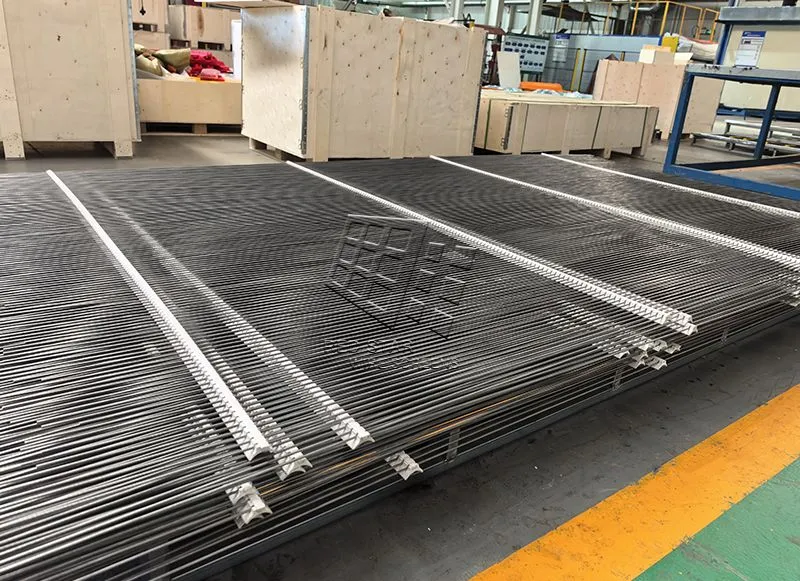

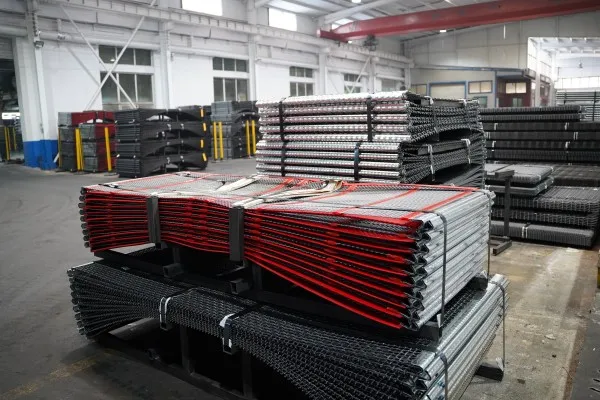

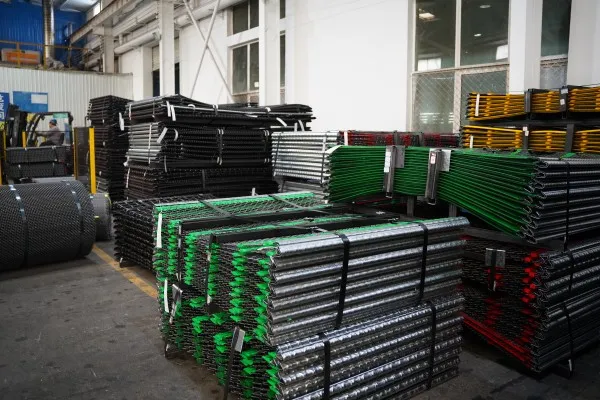

Semi-Finished Piano Wire Screen Panel

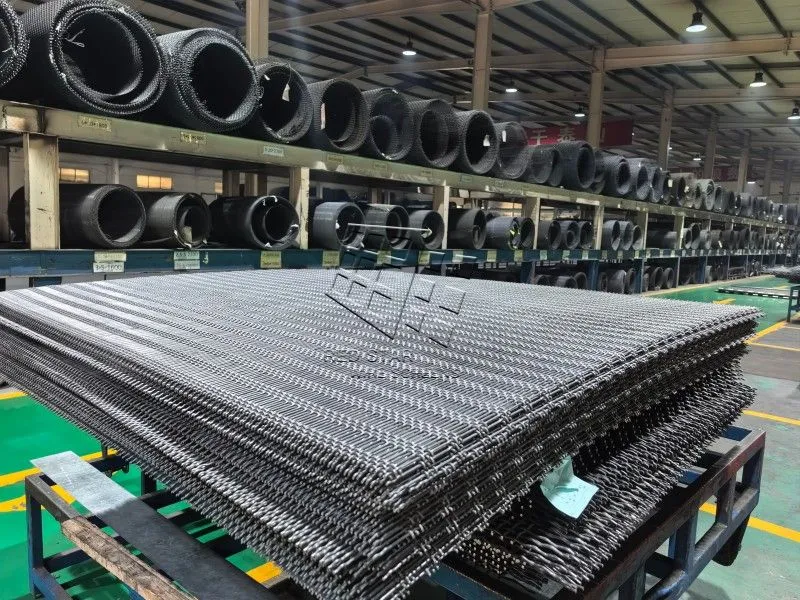

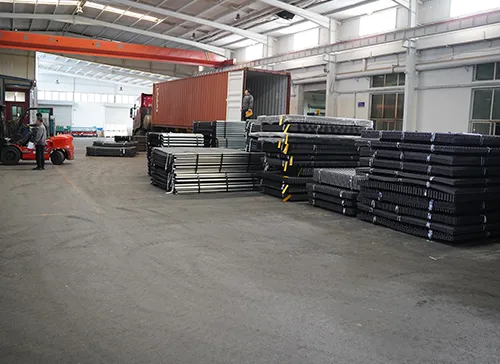

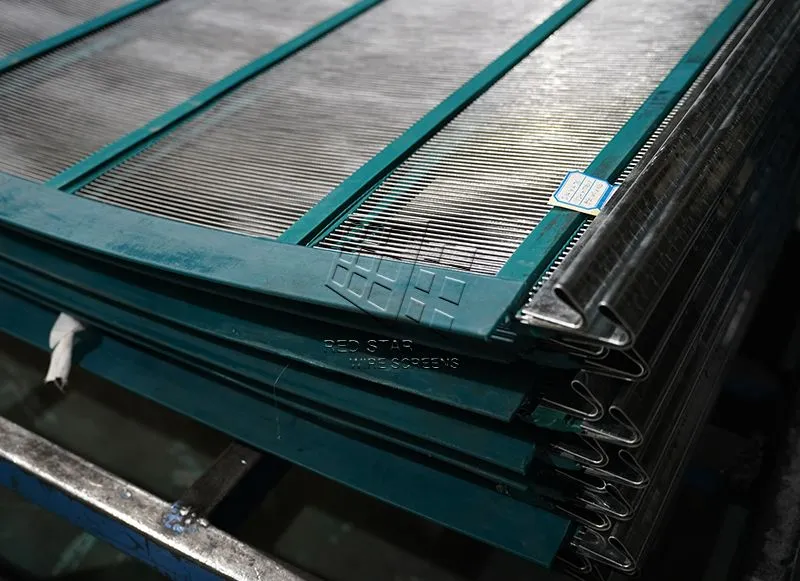

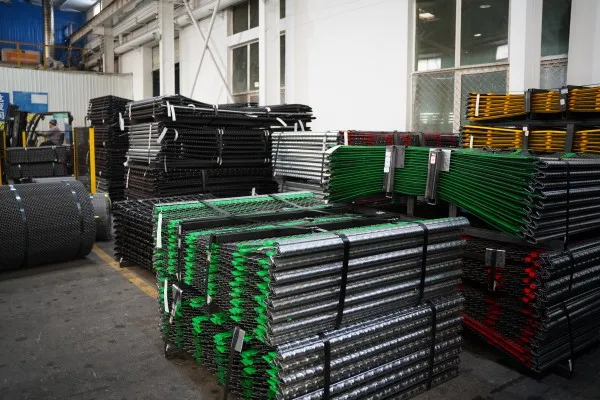

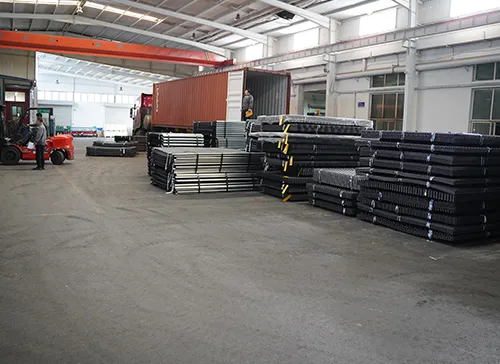

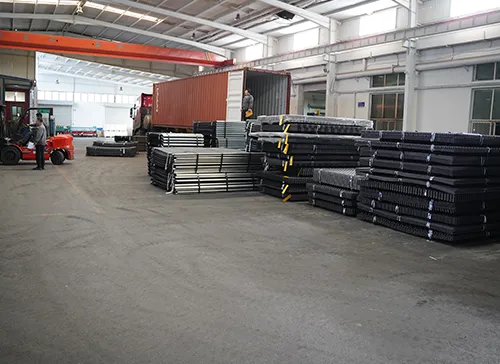

Packaged Piano Wire Screens

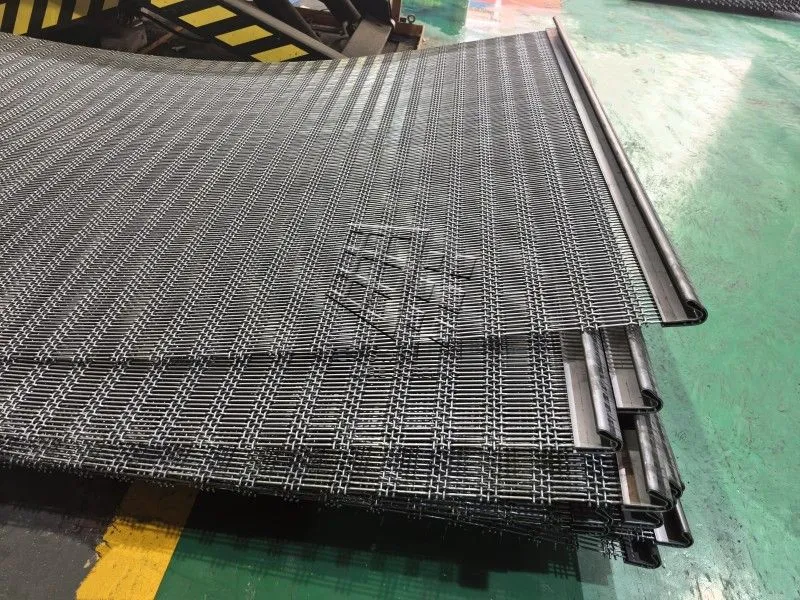

Packaged Piano Wire Screen Panel

Piano Wire Screen Rolls

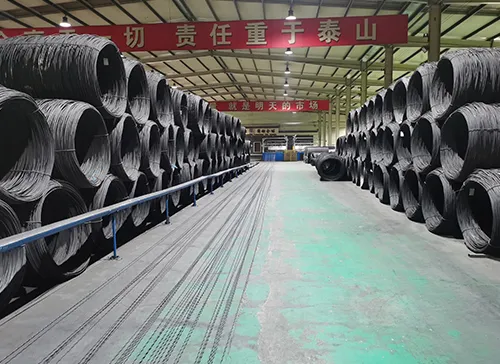

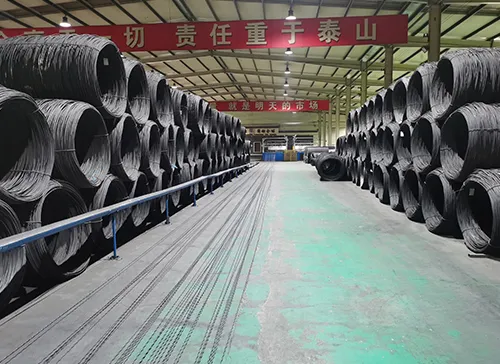

Red Star Wire Mesh Manufacturing Co., Ltd. is a leading supplier with over 36 years of experience in mining screen mesh manufacturing.

Established in 1989 with deep industry expertise

Factory area of 58,730 m² with five specialized workshops

More than 260 sets of advanced production equipment

4000 m² R&D center for wear-resistant materials

18 patented screen mesh products

Drafting unit for China mining self-cleaning screen standards

ISO9001, ISO14001, ISO45001 certified manufacturer

Products exported to over 70 countries worldwide

From raw material sourcing to final inspection, every piano wire screen panel undergoes strict quality control. Advanced wire treatment, precise weaving processes, and comprehensive testing ensure consistent performance and reliability under harsh operating conditions.

Looking for a trusted Piano Wire Screens manufacturer, supplier, or OEM partner? Contact Red Star Wire Mesh today for competitive pricing, technical support, and customized screening solutions tailored to your project requirements.

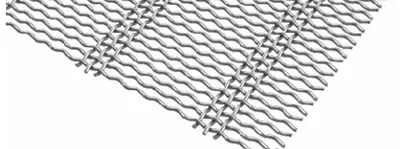

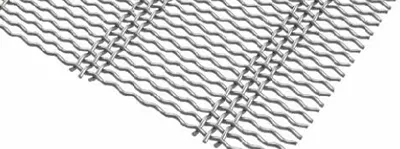

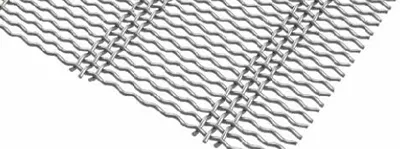

The straight, parallel, tensioned weave provides a smooth, rigid mesh surface with outstanding resistance to tensile deformation, making it suitable for high-vibration and high-load conditions.

The uniform wire pitch and stable mesh size enable efficient grading of coarse and medium-grained materials, meeting the stringent particle size requirements of industries such as mining, sand and gravel aggregates, and more.

The straight wire arrangement reduces material retention, making it suitable for continuous screening of high-volume materials in quarries and coal washeries.

Mesh range: 0.5*2mm-30*150mm

Wire diameter range: 0.5mm-8mm

Type A -piano wire screen

Type A -piano wire screen

Type B -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Custom molding and reinforcement

Final inspection and traceable warehousing

Screen weaving

Screen cutting

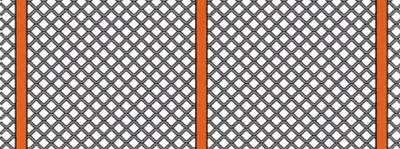

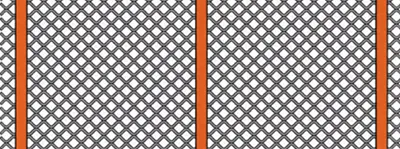

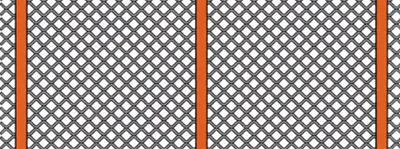

Type 1 -Diamond holes with PU support strips

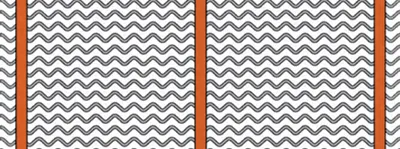

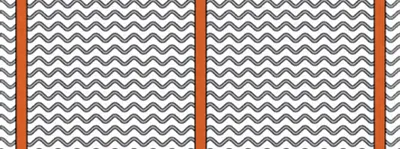

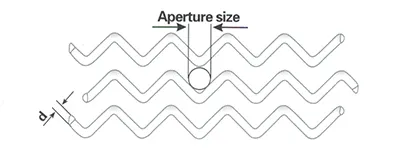

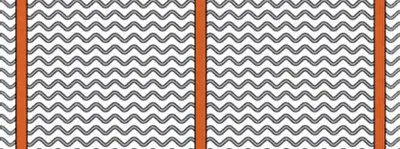

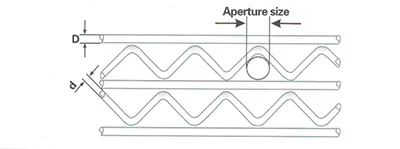

Type 2 -Wave holes with PU support strips

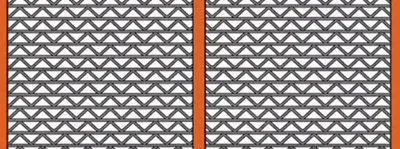

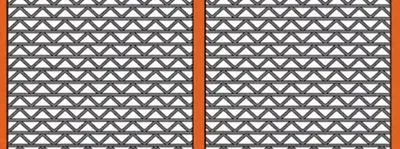

Type 3 -Triangle holes with PU support strips

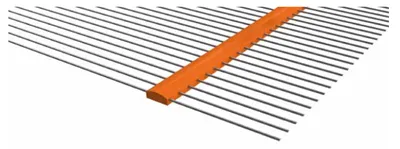

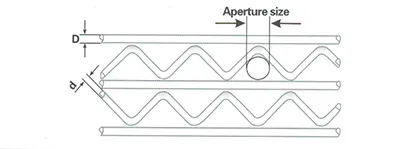

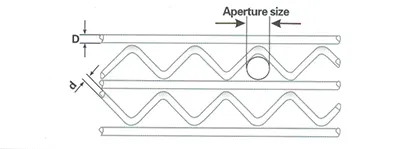

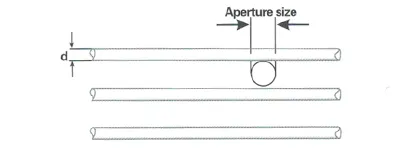

Type 4- piano wire screen with PU support strips

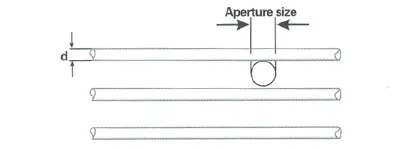

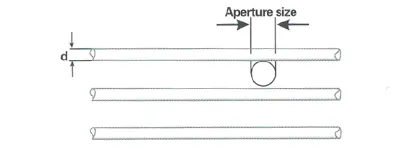

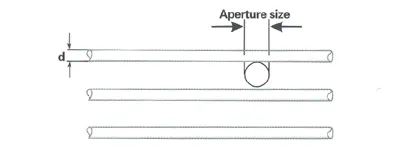

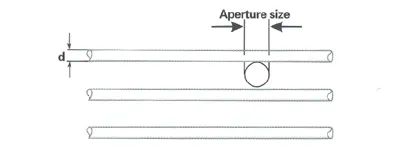

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

The parallel arrangement of straight wires and the regular rectangular pores prevent material from getting stuck (especially for flake and needle-shaped particles).

This reduces fine powder adhesion, improving screening efficiency by over 30% compared to woven mesh, and increasing material throughput.

The polyurethane support bars are fixed, maintaining a constant pore size, ensuring screening efficiency and classification accuracy.

It is suitable for applications such as wet screening and ultrafine powder classification.

It is commonly used for sand screening, especially on mobile screening equipment with longitudinal tension.

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Straight wire screen mesh has regular shape and uniform size, which can accurately screen and classify the materials, and meet the different material particle size requirements in various production processes.

High screening precision, effectively avoid material mis-screening phenomenon caused by screen mesh deformation, mesh irregularity and other reasons, improve product quality and production efficiency.

The screen surface is relatively smooth, not easy to residual material.

It is suitable for screening ores, coal, glass, plastics, food processing, chemical pigments, pharmaceutical granules and so on;

Mesh range: 2mm-60mm

Wire diameter range: 1.37mm-9mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Our experienced staff is available to discuss your needs and to help determine which product is best for your particular application.

Request a quote or call us at +86 187 3080 2171

Red Star Wire Mesh Manufacturing Co., Ltd. is not an authorized repair facility nor does it have an affiliation with the original equipment manufacturers (OEM) listed above. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval of Red Star Wire Mesh Manufacturing Co., Ltd. , Inc. by the named OEM, respectively. All parts are manufactured by, for and warranted by Red Star Wire Mesh Manufacturing Co., Ltd. are not manufactured by, purchased from or warranted by the OEM.

Factory Address:

1 Hongxing Rd, Anping County, Hengshui, Hebei, China

Email:

info@redstarfactory.com

WhatsApp :

+86 187 3080 2171

Phone:

+86 187 3080 2171

WeChat:

+86 187 3080 2171

Working Hours:

Monday – Friday: 8:00 AM – 5:00 PM (GMT+8). We reply to all inquiries within 12–24 hours, regardless of time zone.