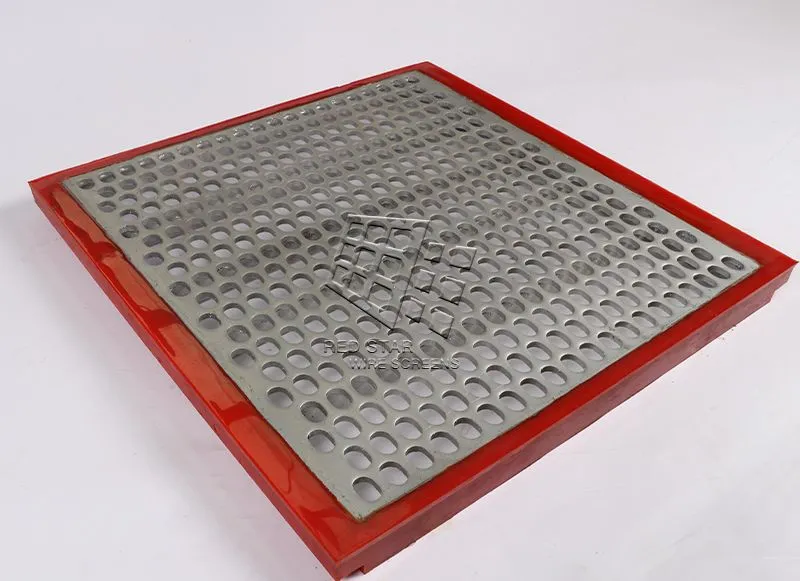

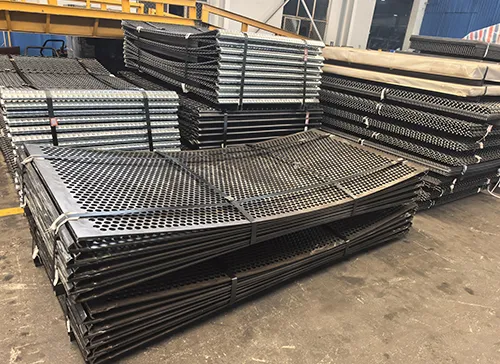

Perforated plate screen is a kind of screen that forms uniform holes on metal plates by mechanical stamping process.

It is usually made of stainless steel, carbon steel, aluminum and other high-strength materials, with good wear resistance and corrosion resistance.

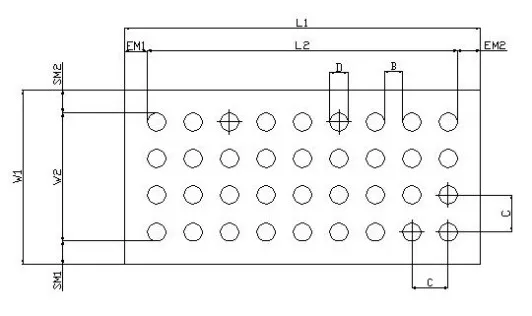

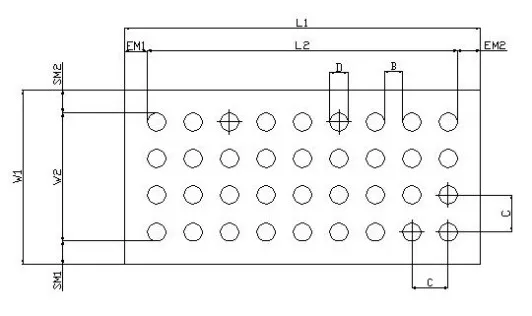

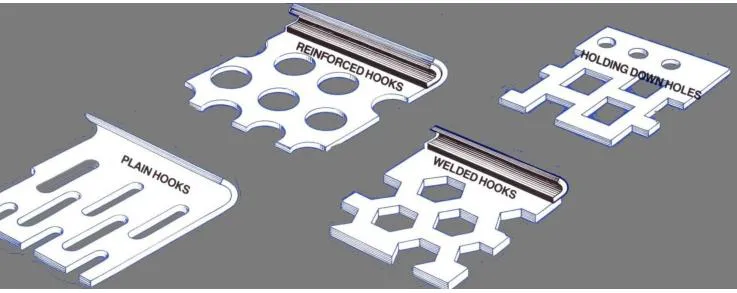

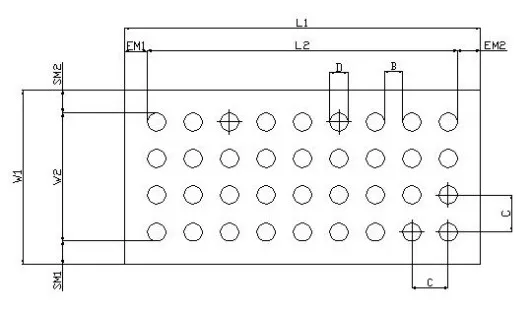

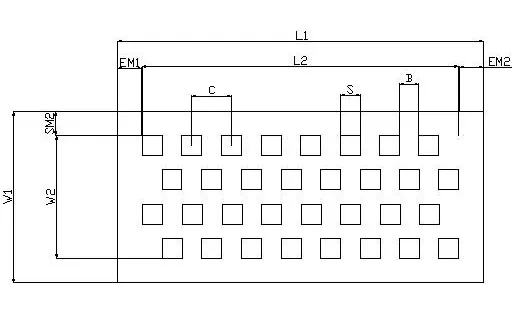

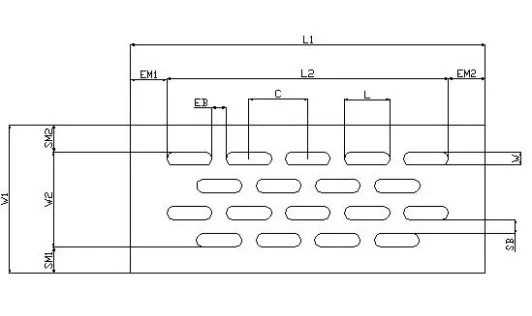

Round holes in a straight row

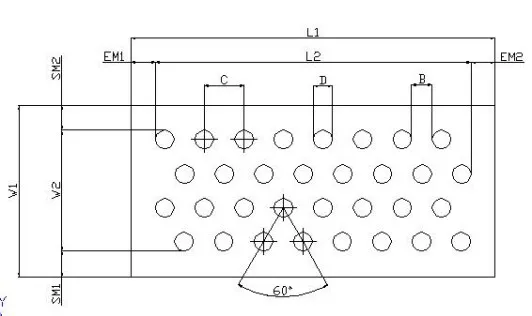

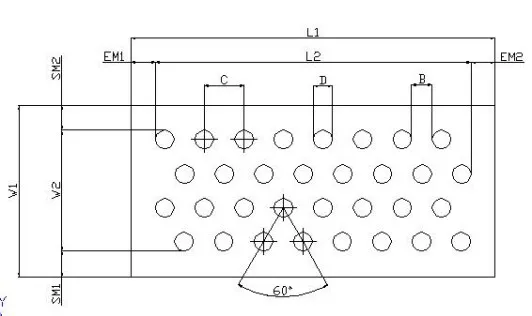

Round holes in a staggered pattern

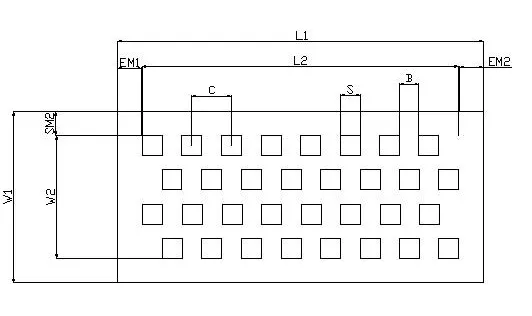

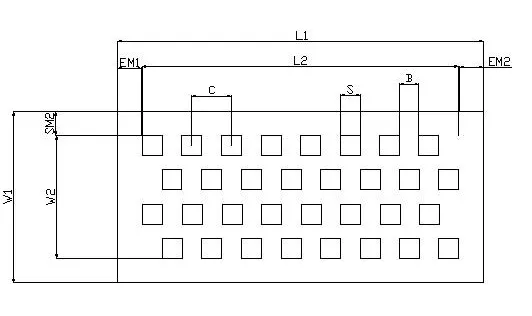

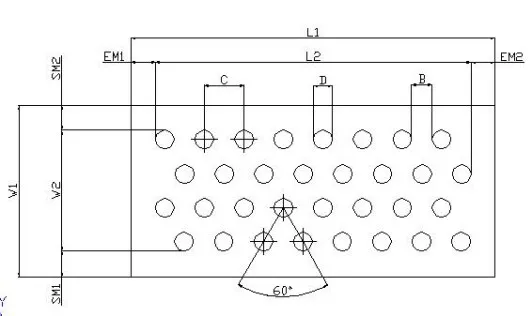

Square holes

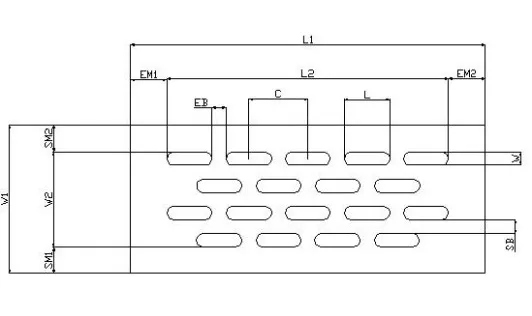

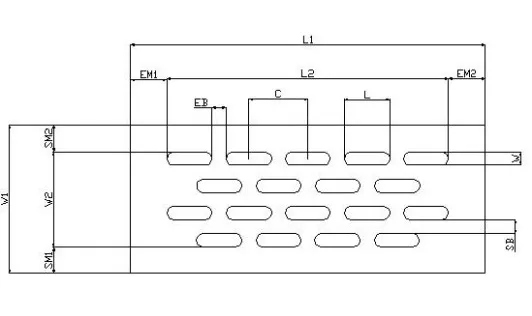

Slotted holes

Perforated plate screen is a kind of screen that forms uniform holes on metal plates by mechanical stamping process.

Perforated plate screen is a kind of screen that forms uniform holes on metal plates by mechanical stamping process.

It is usually made of stainless steel, carbon steel, aluminum and other high-strength materials, with good wear resistance and corrosion resistance.

The mesh of perforated plate screen has uniform precision and is not easily deformed, which is suitable for screening large particles.

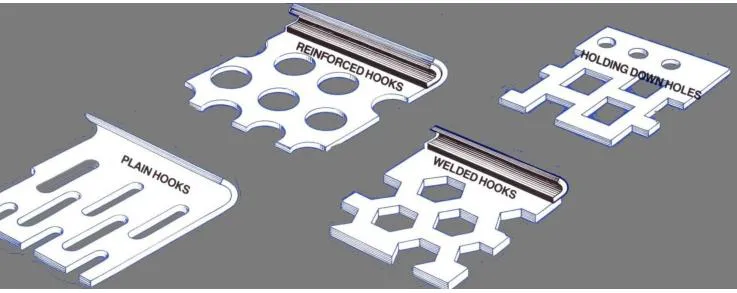

Perforated plate screen mesh has various hole shapes, such as rectangular, square, diamond, round, hexagonal, oblong, irregular, etc., which can meet different screening needs.

Perforated screen mesh is not only used in the mining industry, but can also be used in a variety of industries for screening, filtration, protection, decoration, and so on.

Efficient screening, wear resistance and impact resistance, customized solutions

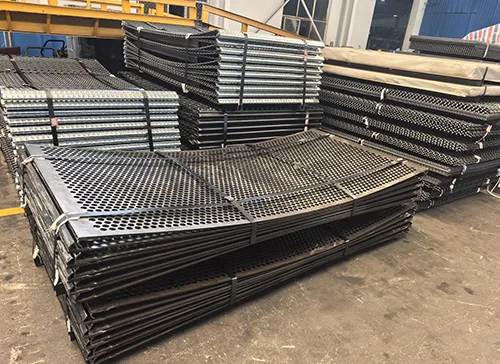

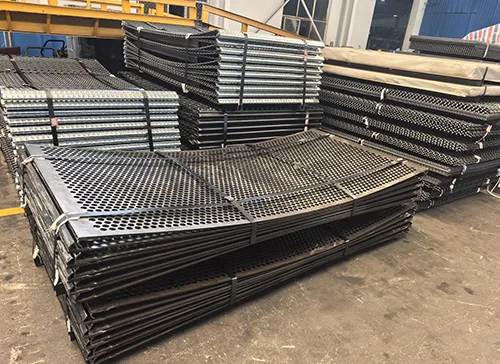

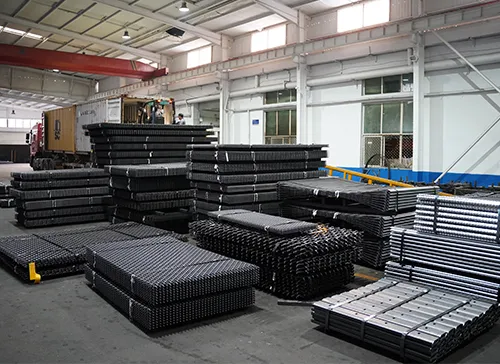

Mining perforated screen plates are core components of key processes such as material grading, screening, and dehydration in mining, metallurgy, and building materials industries.

Wear -resistant and impact-resistant

It uses NM400/NM500 grade high-strength wear-resistant steel (thickness 8-30mm) with a hardness of HB400-500. Its service life is more than 3 times that of ordinary sieve plates , and the annual maintenance cost is reduced by about 40% .

Precision screening control

Laser/CNC precision drilling, aperture tolerance ±0.1mm, supports customized apertures from φ5-100mm, ensuring accurate grading of ore /coal/aggregate particle size, and improving mineral processing efficiency by more than 25% .

Super strong carrying capacity

The tensile strength is ≥1200MPa, the dynamic bearing load is up to 5 tons/㎡, it can withstand high-frequency vibration and ore impact, and prevent deformation and cracking.

Flexible customization

Support non-standard size and special-shaped hole design

| Material | Suitable Application | Feature Highlights |

| High-carbon steel | Limestone, coal screening | High cost performance, strong impact resistance |

| Manganese steel | Heavy-duty pre-crushing screening | Self-hardening; becomes tougher with wear |

| Stainless steel 304/316 | Salt mines, slurries, corrosive environments | Acid & alkali resistant, 3× longer service life |

| Polyurethane (PU) | Fine particle sizing (<3 mm) | 40 % noise reduction, anti-adhesion |

Ore initial screening : the first screening in the mine to remove large-sized waste rock

Concentrate classification : copper/iron/gold ore is separated precisely by particle size

Coal washing plant : coal dehydration and desludging process

Aggregate processing : sand and gravel classification (0-100mm particle size control)

Recycled resources : construction waste, metal scrap sorting

International certification: ISO 9001 quality system

Global service: 36 years of export experience, serving mining projects in 70+ countries

Free design support: Provide CAD drawings to optimize screening solutions

Full process guarantee:

✓ Material composition report ✓ Anti-rust export packaging ✓ Door-to-door shipping by sea or air

Round holes in a straight row

Round holes in a staggered pattern

Square holes

Slotted holes

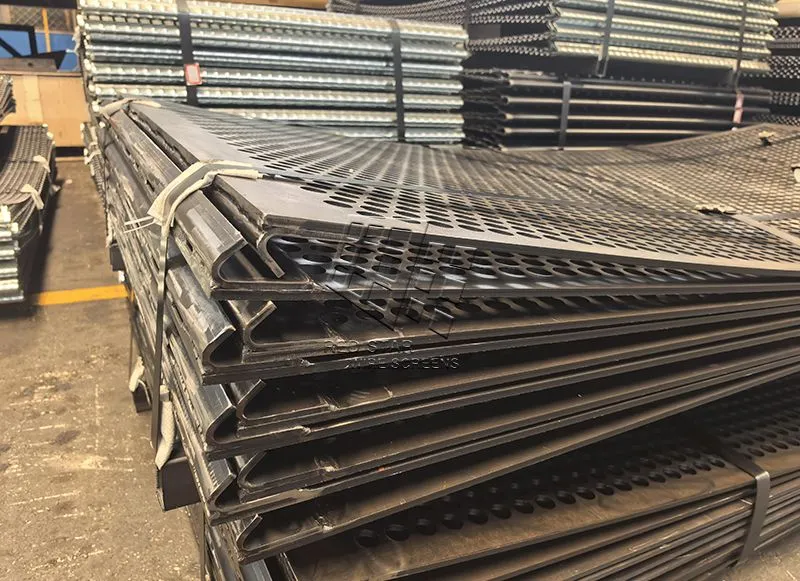

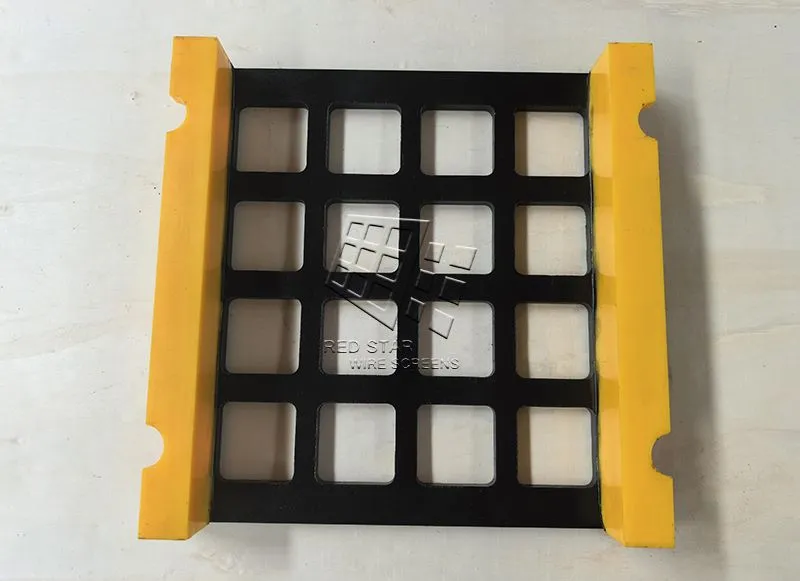

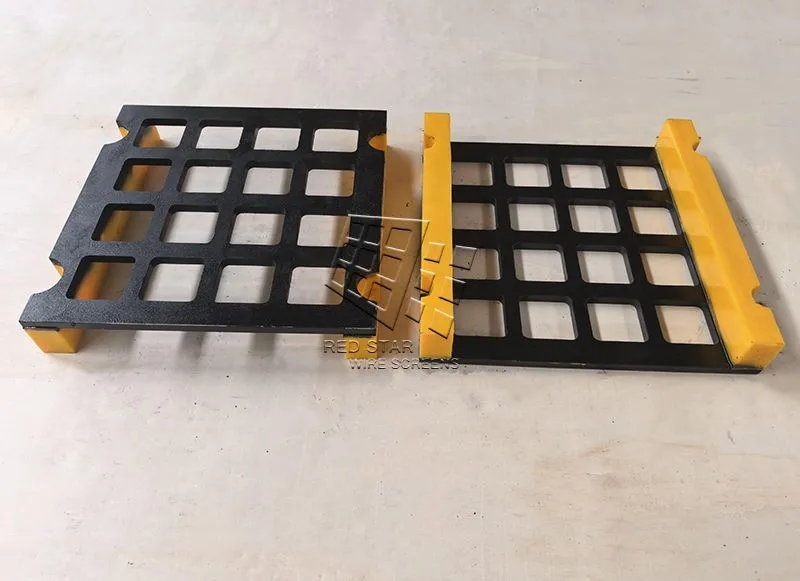

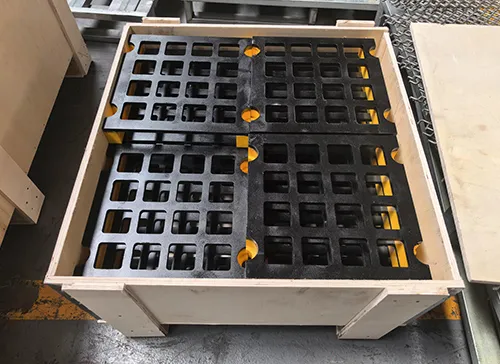

The polyurethane-edged perforated screen plate overcomes the three major pain points of wear, clogging, and noise in the screening industry through the composite design of "metal rigidity + polymer elasticity" .

The polyurethane-edged perforated screen plate overcomes the three major pain points of wear, clogging, and noise in the screening industry through the composite design of "metal rigidity + polymer elasticity" . With long life, stable precision, and low maintenance as its core value, it directly reduces customers' comprehensive operating costs by more than 30 %.

Super wear-resistant life, impact resistance and deformation resistance, more stable screening

- Polyurethane wrapped perforated screen plate edge, resists ore impact wear, life is increased by 3-5 times - Solve

the problem of frequent replacement caused by cracking and deformation of traditional screen plate edges

Reduce noise and vibration, improve the working environment

- The damping properties of polyurethane materials can reduce the vibration noise

of the screen by 15-20dB, reducing the risk of equipment resonance. - Improve operating comfort, meet environmental requirements, and extend the life of the screen bearings.

Completely eliminate material jamming

- the polyurethane elastic frame tightly fills the gaps in the screen frame, achieving 100% no jamming

- ensuring continuous screening efficiency and reducing downtime for cleaning

Anti-corrosion, resistant to wet and sticky materials

- Polyurethane edging is resistant to acids, alkalis, and hydrolysis, making it resistant to corrosive media such as mining wastewater and coal washing fluids. Perforated steel plates are available with optional anti-corrosion treatments (such as galvanizing and plastic spraying).

- Suitable for wet and corrosive environments such as coal washing plants and sea sand screening, preventing rust-induced mesh enlargement and failure.

Lightweight installation doubles maintenance efficiency

- 30% lighter than all-steel screen panels, the modular design allows for quick clip/bolt installation.

- Screen panels can be replaced by a single person, reducing maintenance time by 50%, lowering labor costs and safety risks.

| Feature | Traditional Steel Screen Plate | Polyurethane-Edged Screen Plate |

|---|---|---|

| Edge Wear | Prone to curling and cracking | Elastic edge distributes stress, ↑ lifespan |

| Plugging Rate | High (sharp edges catch material) | Low (smooth PU edge guides material) |

| Noise Level | > 90 dB | < 75 dB |

| Wet Screening Ability | Rusting & clogging prone | Hydrophobic & non-stick, ↑ 20 % screening efficiency |

1. Accurate size compatibility

- Support all types of vibrating screens (banana screen/circular vibrating screen/linear screen)

- Frame thickness 20-50mm, flexible customization

2. Customized working conditions

pore size + porosity combinations by ore type (coal/iron ore/gold ore)

Stainless steel sieve plate + acid-resistant polyurethane solution for highly corrosive environments

Ore initial screening : the first screening in the mine to remove large-sized waste rock

Concentrate classification : copper/iron/gold ore is separated precisely by particle size

Coal washing plant : coal dehydration and desludging process

Aggregate processing : sand and gravel grading ( 5-100mm particle size control)

Recycled resources : construction waste, metal scrap sorting

Round holes in a straight row

Round holes in a staggered pattern

Square holes

Slotted holes

Our experienced staff is available to discuss your needs and to help determine which product is best for your particular application.

Request a quote or call us at +86 187 3080 2171

Red Star Wire Mesh Manufacturing Co., Ltd. is not an authorized repair facility nor does it have an affiliation with the original equipment manufacturers (OEM) listed above. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval of Red Star Wire Mesh Manufacturing Co., Ltd. , Inc. by the named OEM, respectively. All parts are manufactured by, for and warranted by Red Star Wire Mesh Manufacturing Co., Ltd. are not manufactured by, purchased from or warranted by the OEM.

Factory Address:

1 Hongxing Rd, Anping County, Hengshui, Hebei, China

Email:

info@redstarfactory.com

WhatsApp :

+86 187 3080 2171

Phone:

+86 187 3080 2171

WeChat:

+86 187 3080 2171

Working Hours:

Monday – Friday: 8:00 AM – 5:00 PM (GMT+8). We reply to all inquiries within 12–24 hours, regardless of time zone.