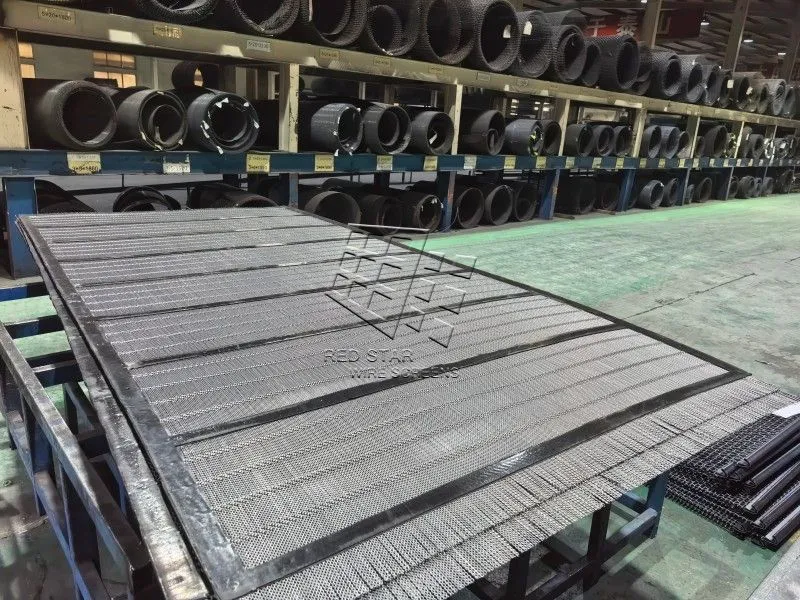

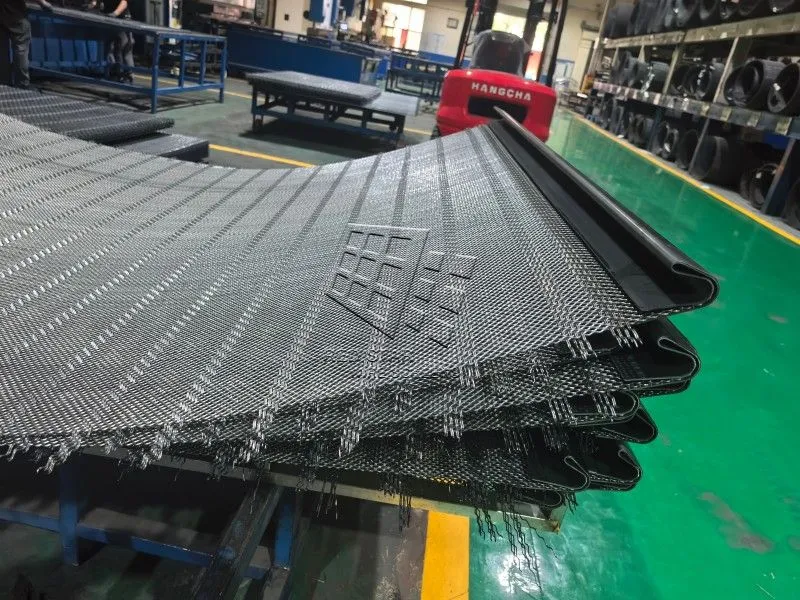

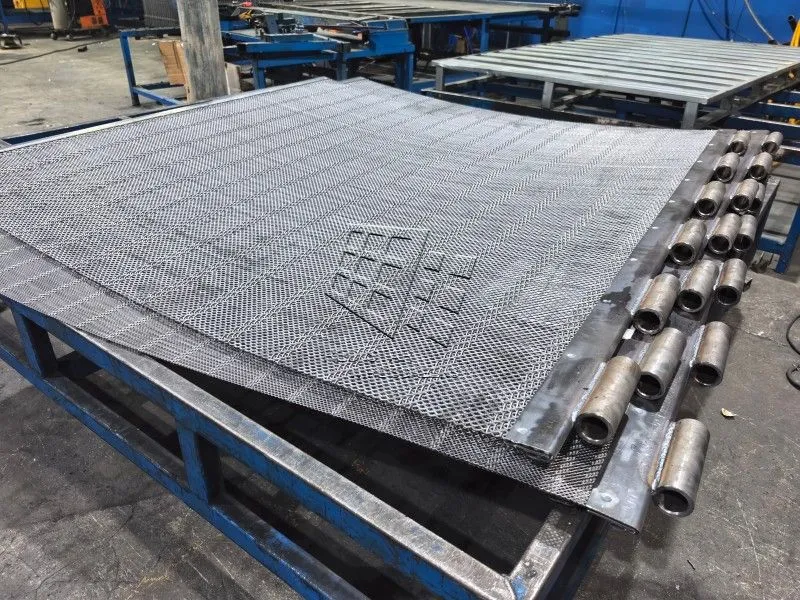

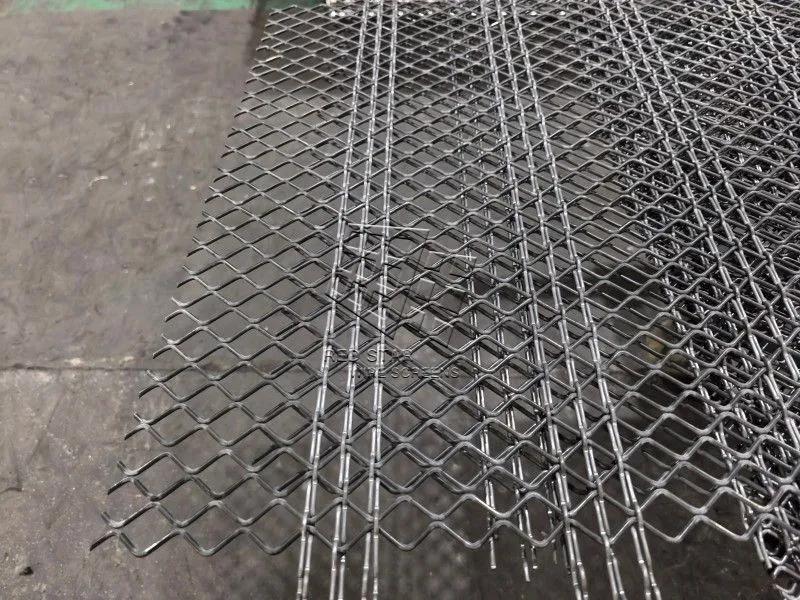

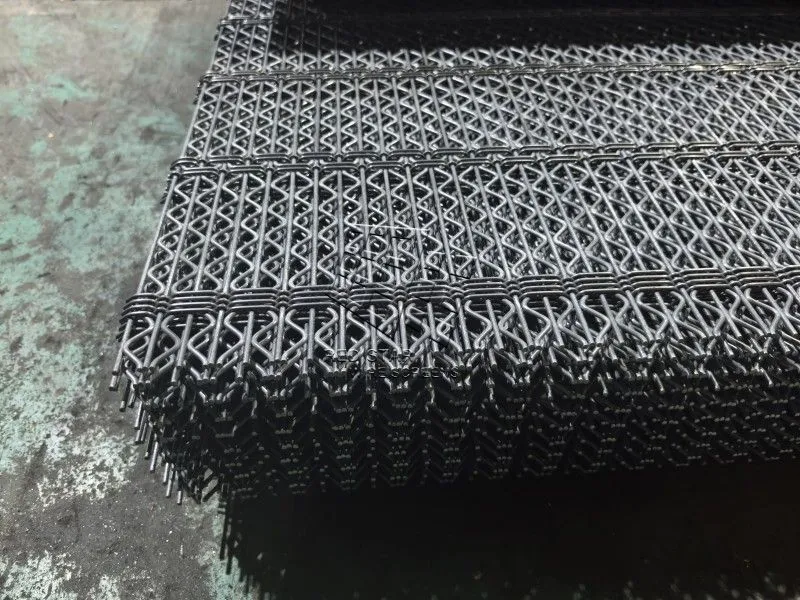

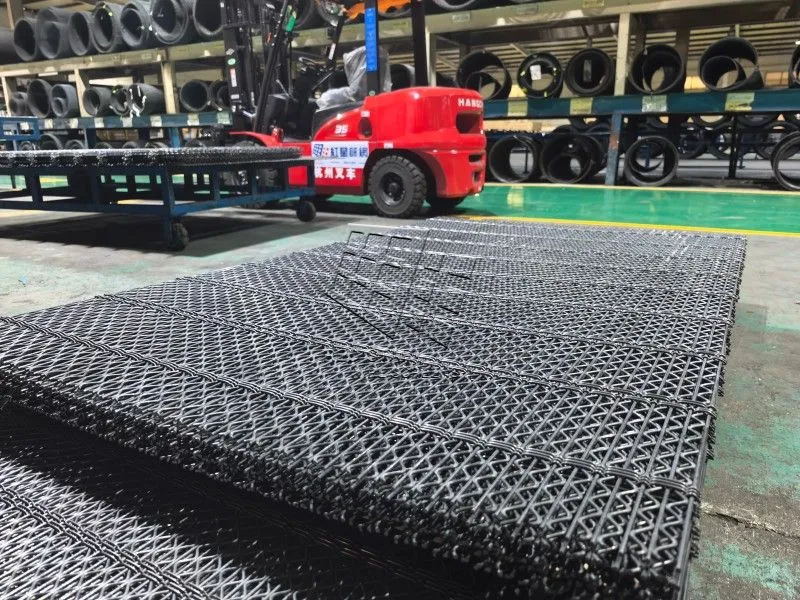

Clog-resistant self-cleaning screen mesh provides effective solutions for sticky and moist materials. The unique crimped and bonded wire structure prevents material blockage, improves throughput, and guarantees consistent performance, especially in wet screening applications.

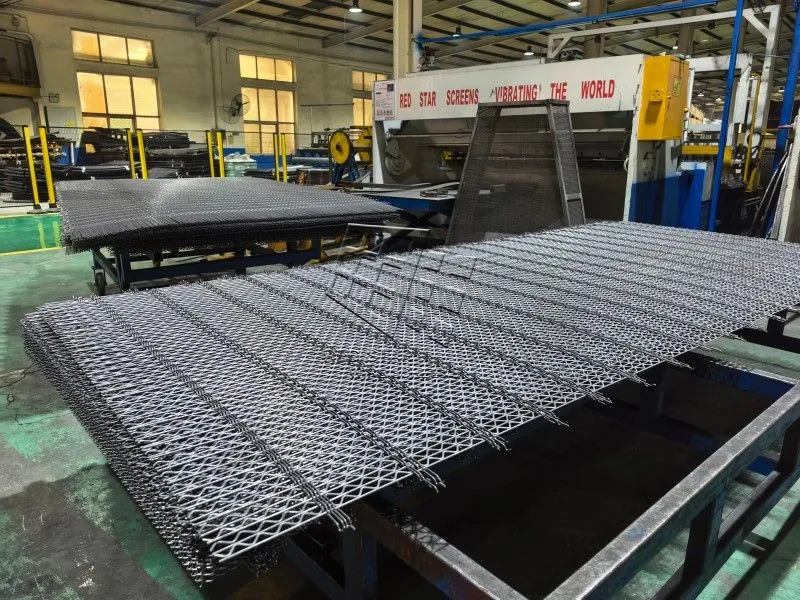

Self-Cleaning Screens are advanced anti-blinding screening meshes engineered to reduce clogging, material buildup, and downtime in challenging screening conditions. Manufactured with specially crimped or independently vibrating wires, each wire moves freely during operation to prevent blinding, pegging, and blocking—particularly when handling damp, sticky, or fine materials.

Widely used in mining, aggregate, coal, and asphalt processing, self-cleaning screens deliver higher screening efficiency and stable performance worldwide.

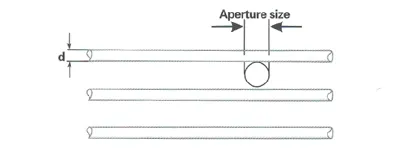

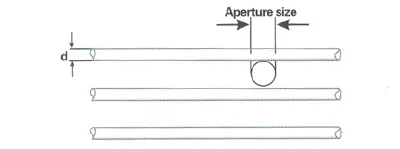

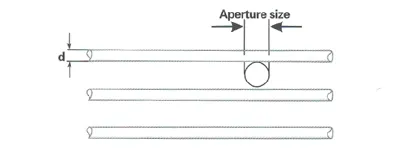

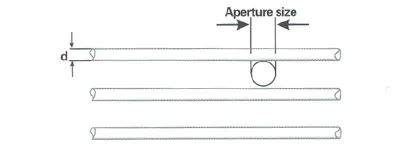

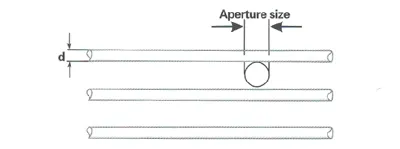

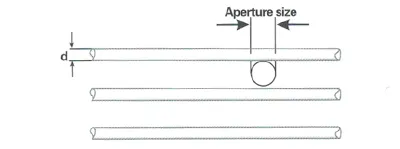

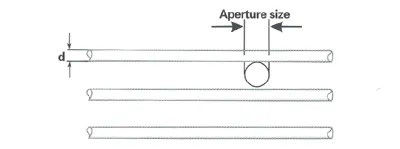

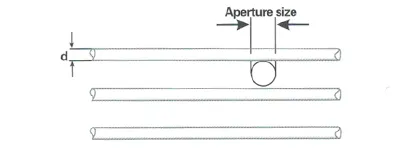

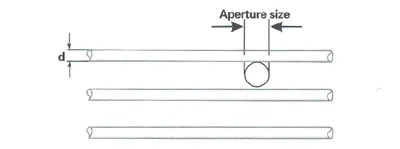

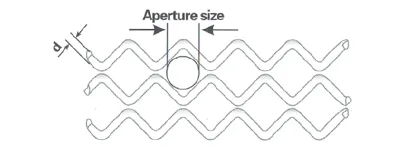

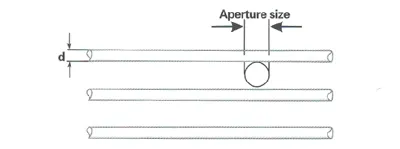

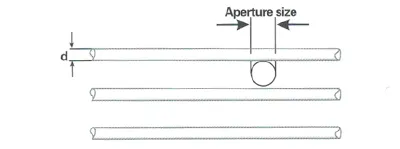

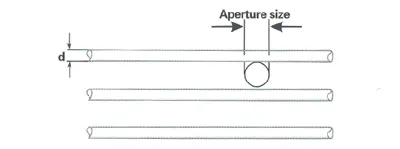

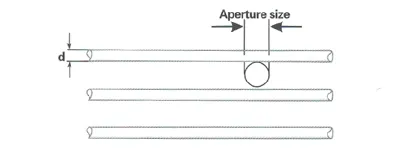

Mesh Range: 2 mm – 60 mm

Wire Diameter Range: 1.37 mm – 9 mm

Wire Material: High Carbon Steel, Spring Steel, Stainless Steel (Optional)

Panel Width: Up to 2,500 mm

Panel Length: Custom to Vibrating Screen Type

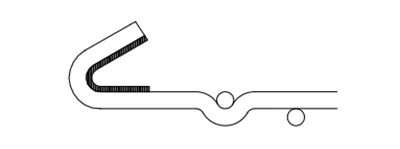

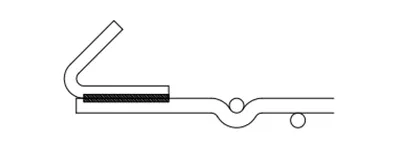

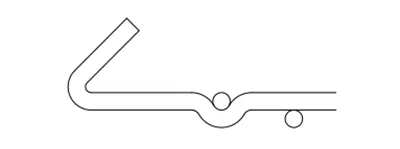

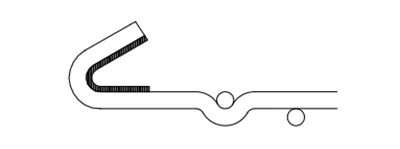

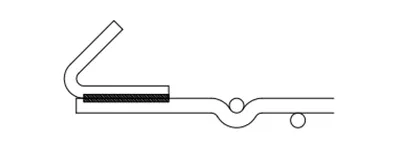

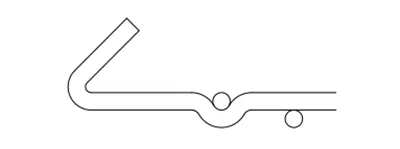

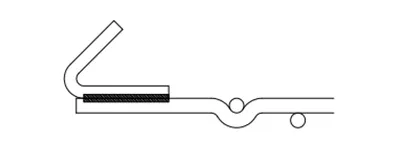

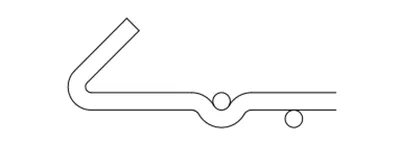

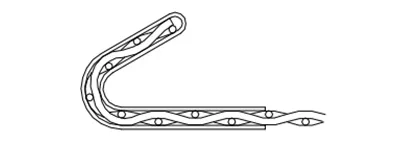

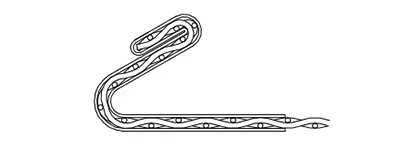

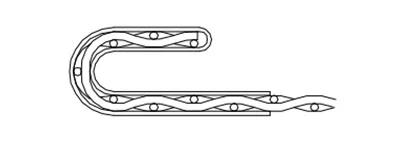

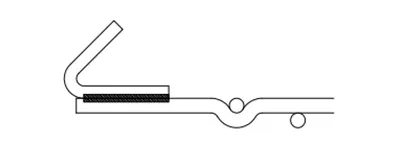

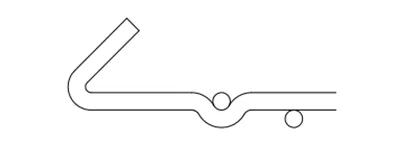

Edge Options: Hook Edge, Flat Bar, Bolt-Down Edge

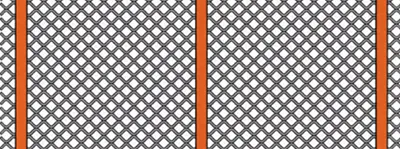

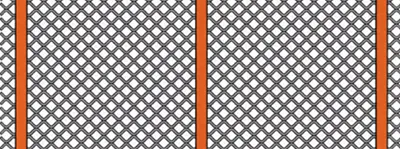

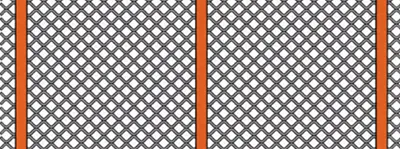

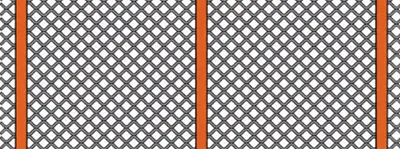

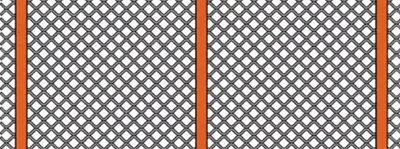

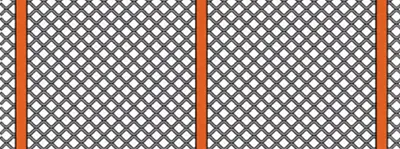

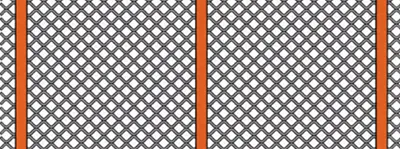

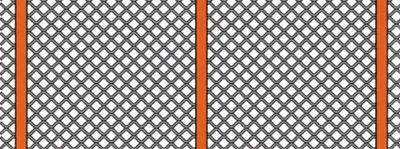

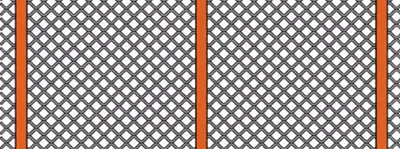

Type 1 -Diamond holes with PU support strips

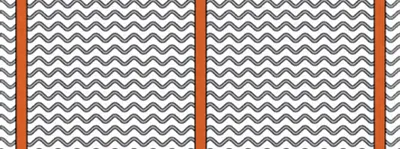

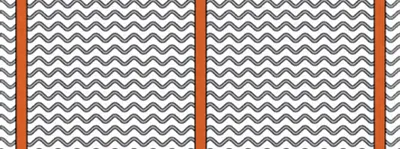

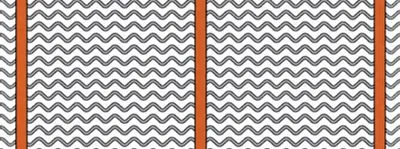

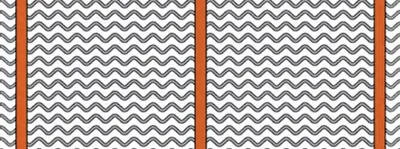

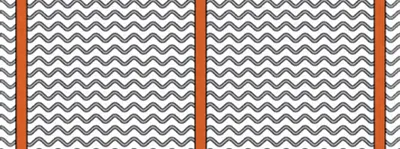

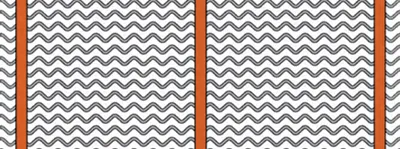

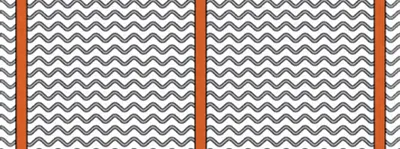

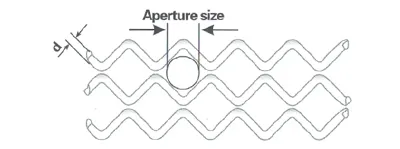

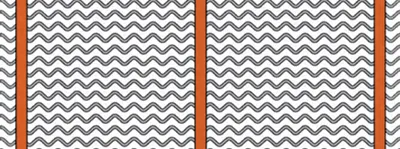

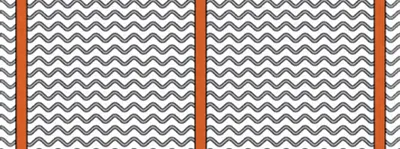

Type 2 -Wave holes with PU support strips

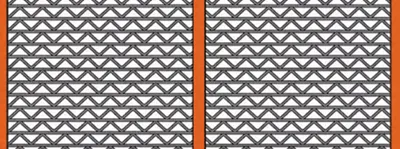

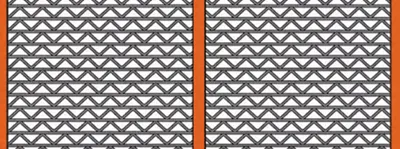

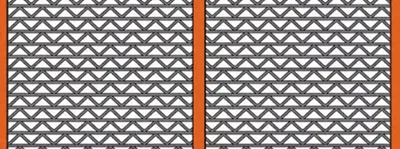

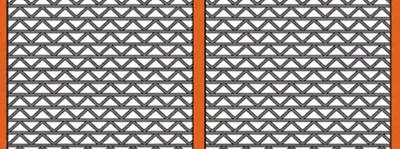

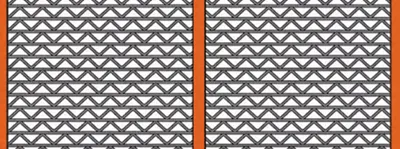

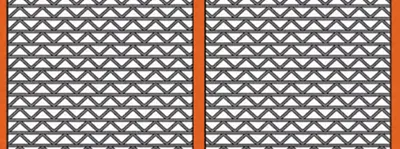

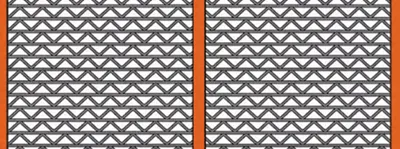

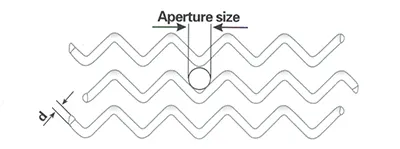

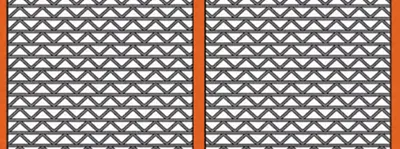

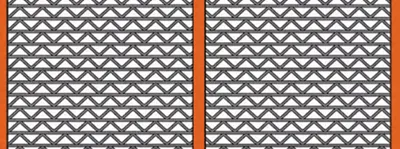

Type 3 -Triangle holes with PU support strips

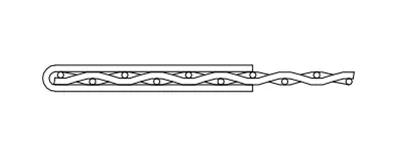

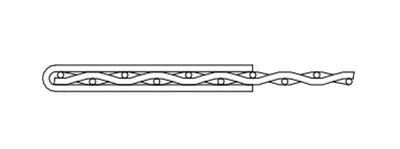

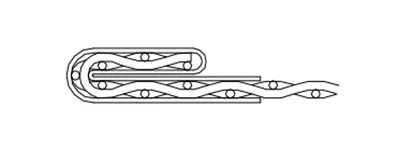

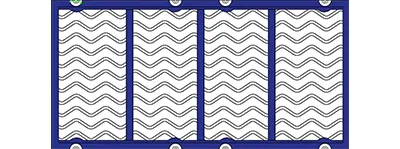

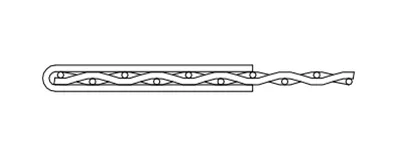

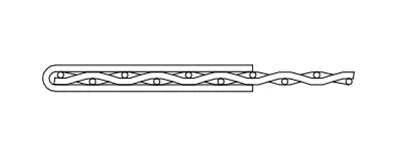

Type 4- piano wire screen with PU support strips

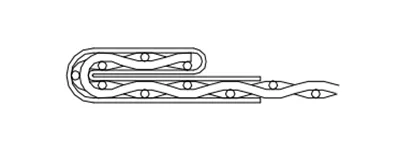

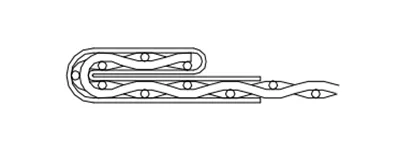

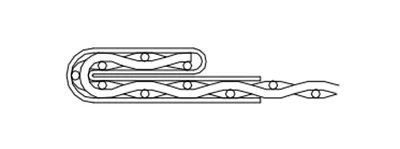

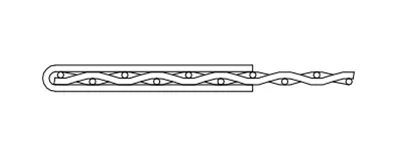

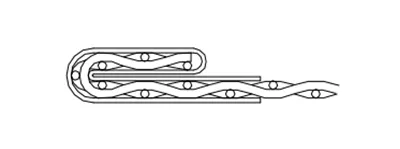

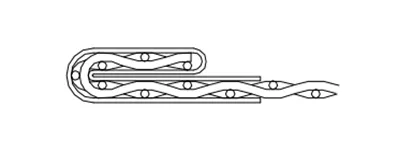

Type 5- piano wire screen-Removable support bar

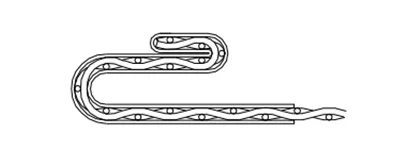

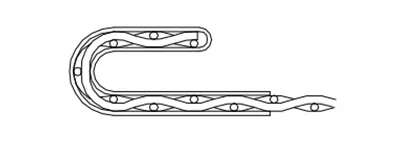

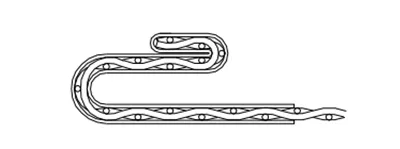

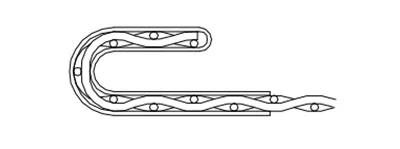

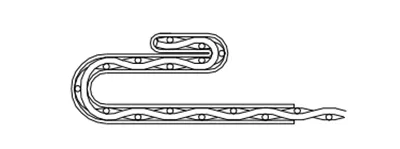

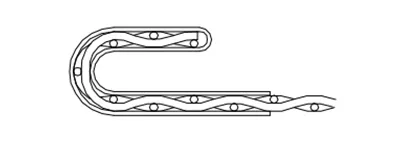

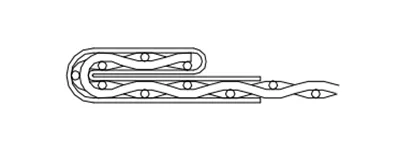

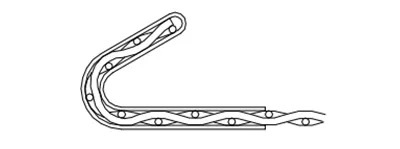

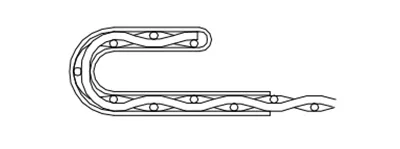

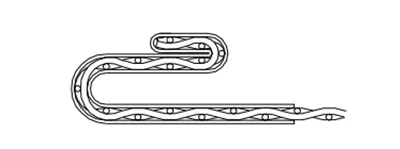

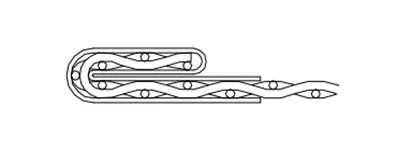

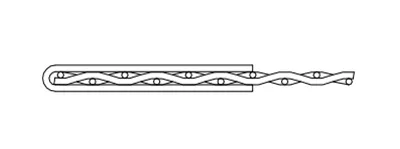

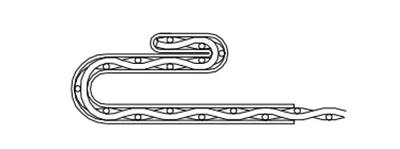

Type A -piano wire screen

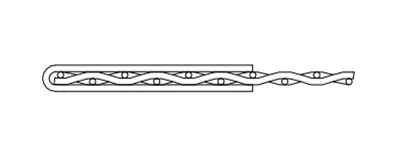

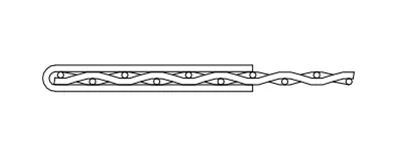

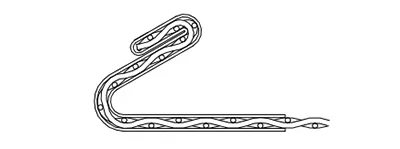

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

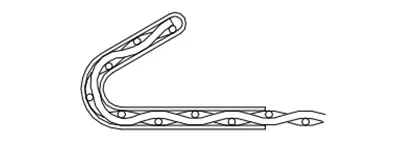

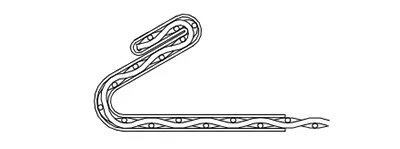

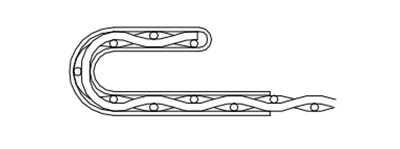

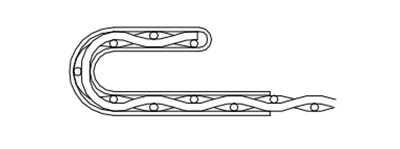

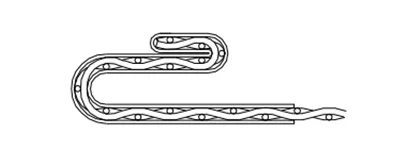

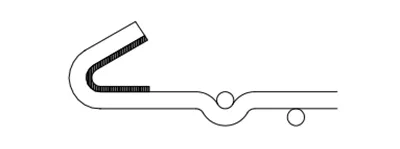

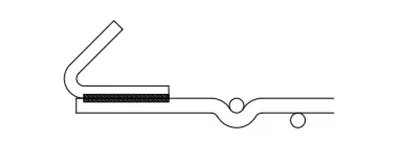

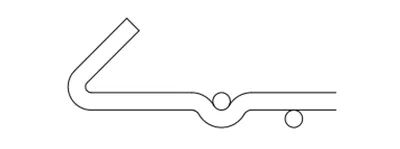

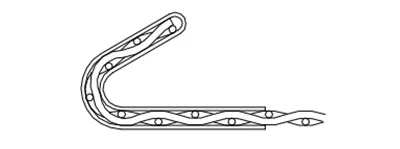

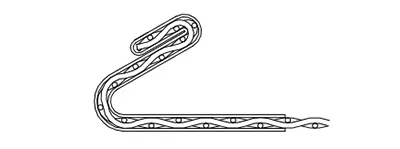

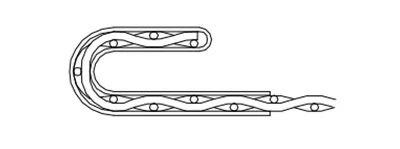

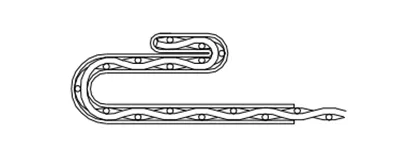

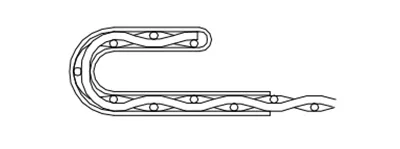

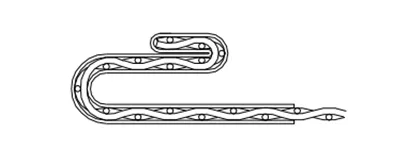

Type A -piano wire screen

Type B -piano wire screen

Excellent anti-blinding and anti-clogging performance

Higher screening efficiency and throughput capacity

Reduced downtime and maintenance costs

Longer service life compared to conventional woven wire screens

Ideal for wet, sticky, and difficult-to-screen materials

Self-cleaning screen mesh is widely used in industries where traditional wire screens struggle:

Mining and mineral processing

Quarry and aggregate production

Coal screening and washing plants

Sand and gravel classification

Asphalt mixing plants

Recycling and waste separation

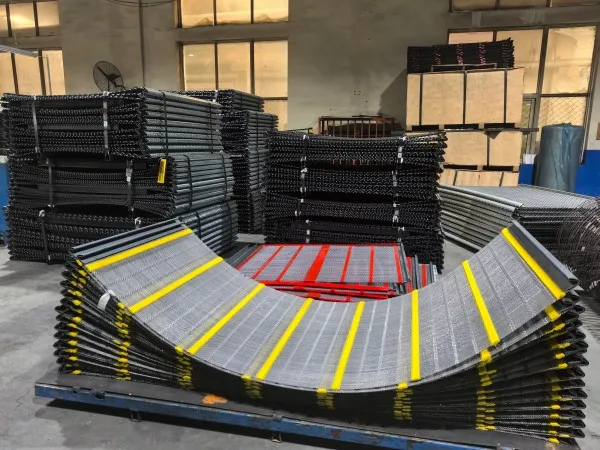

Red Star Wire Mesh provides custom self-cleaning screens and OEM manufacturing services tailored to your vibrating screen model, capacity requirements, and material characteristics. Custom aperture sizes, wire diameters, panel dimensions, and edge types are all available to ensure optimal screening performance.

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

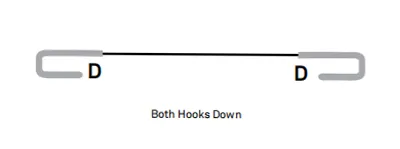

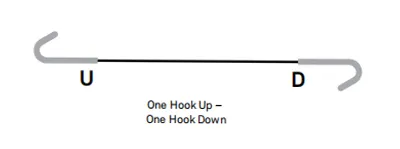

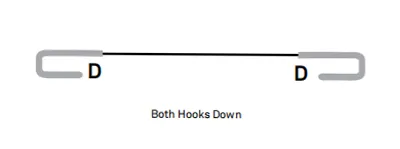

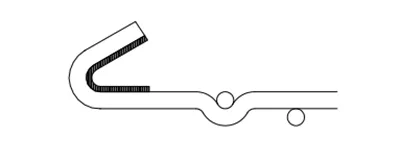

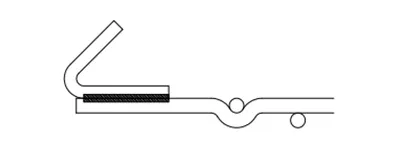

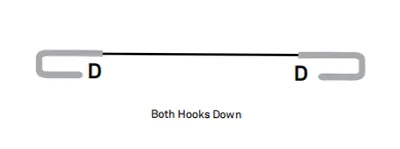

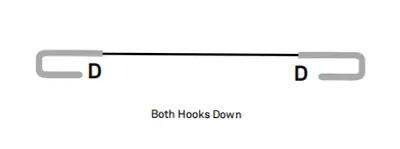

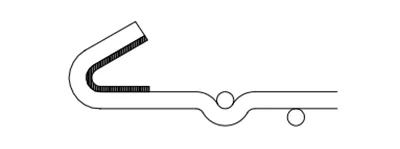

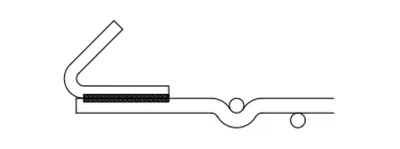

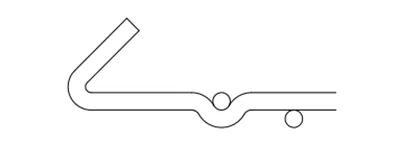

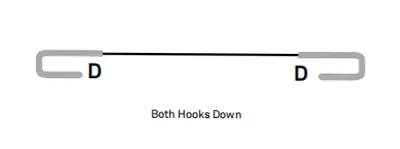

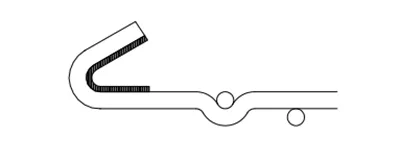

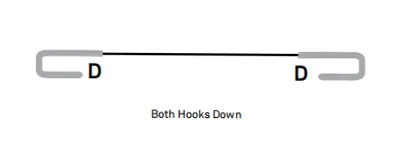

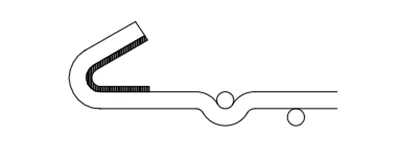

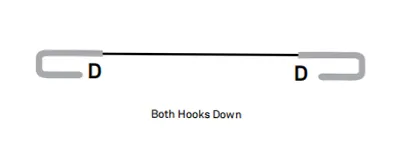

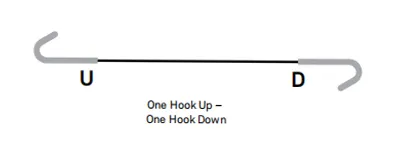

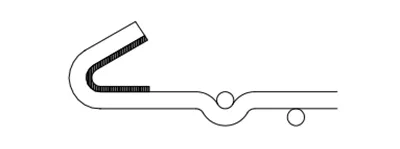

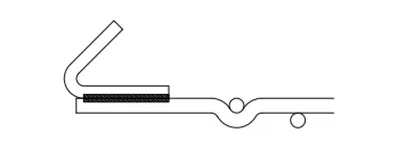

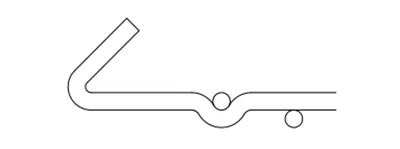

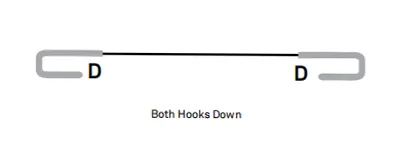

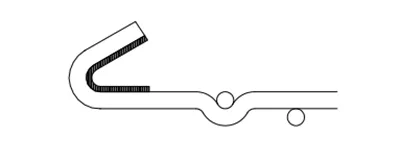

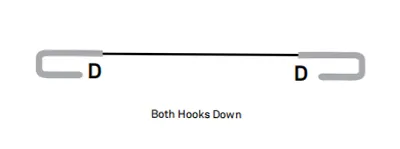

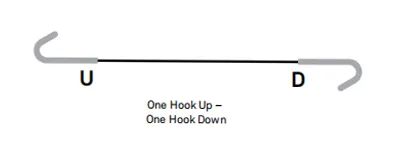

Both Hooks Down

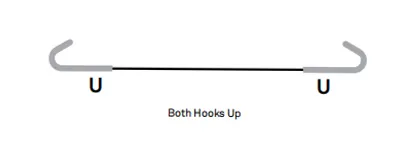

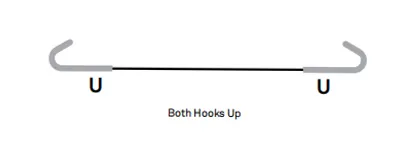

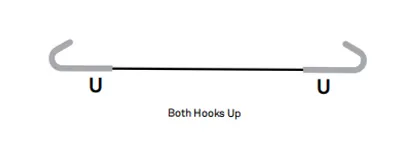

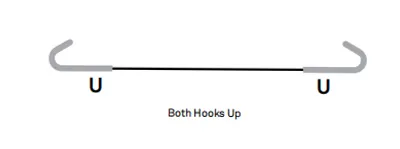

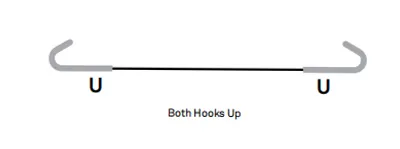

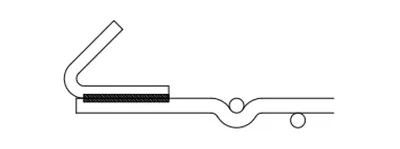

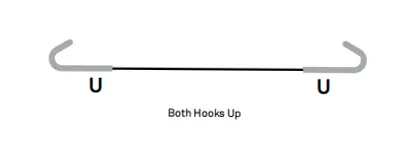

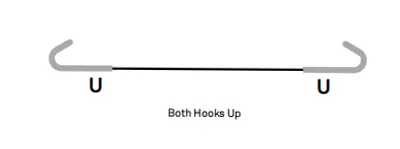

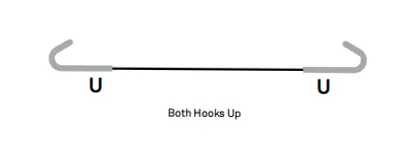

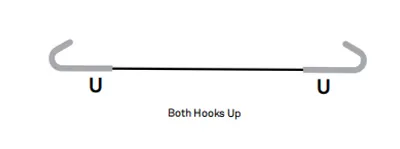

Both Hooks Up

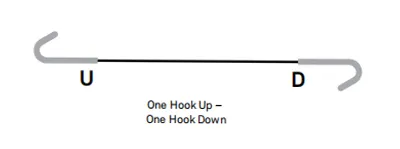

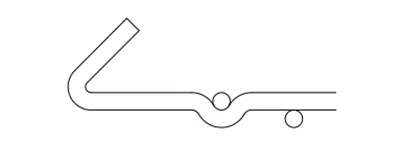

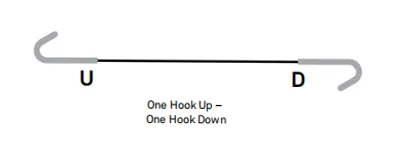

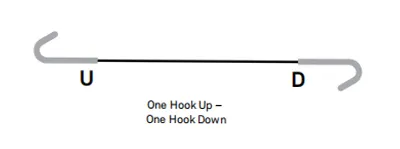

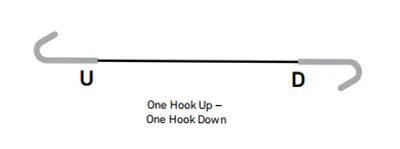

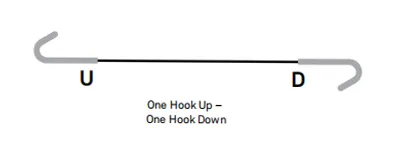

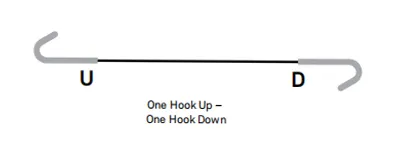

One Hook Up and One Hook Down

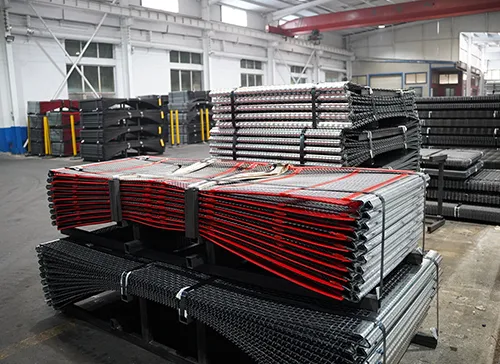

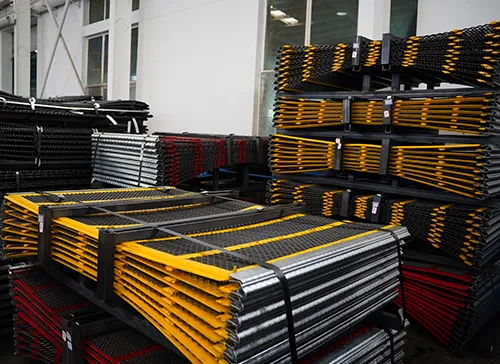

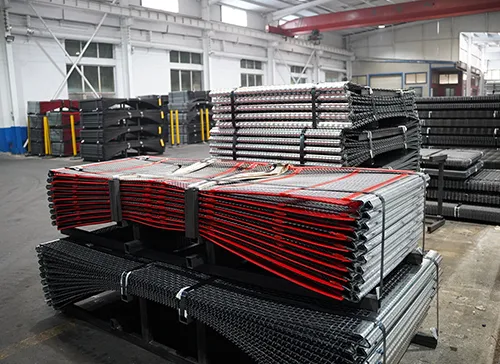

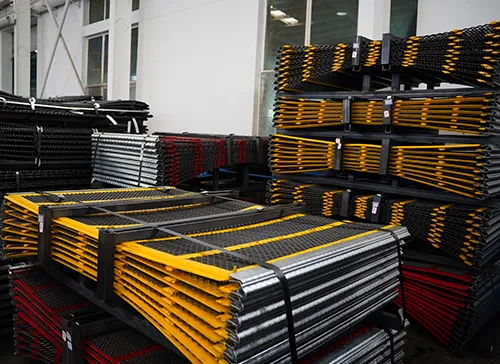

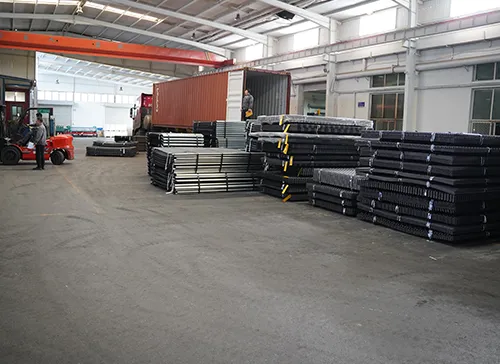

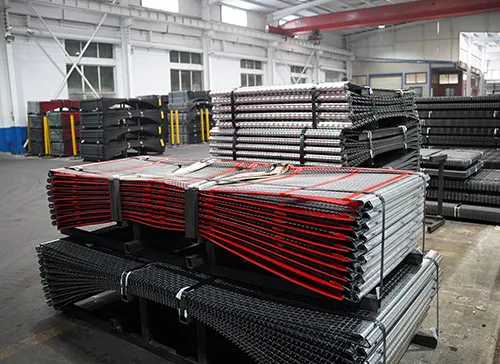

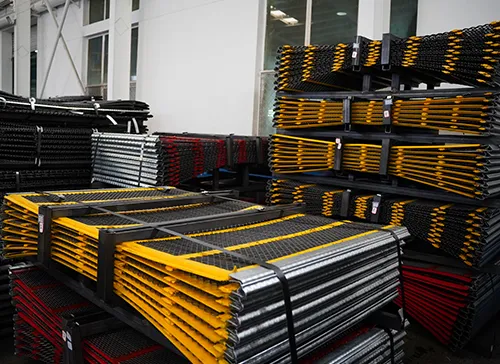

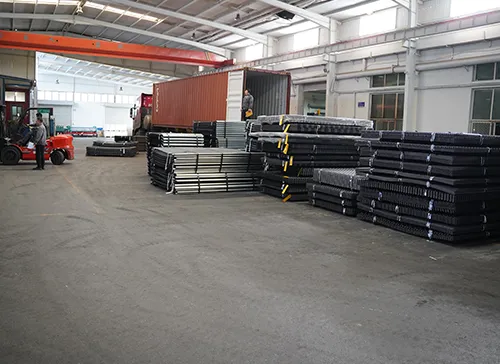

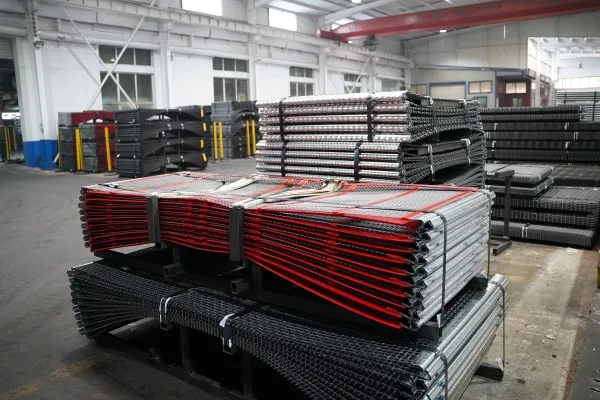

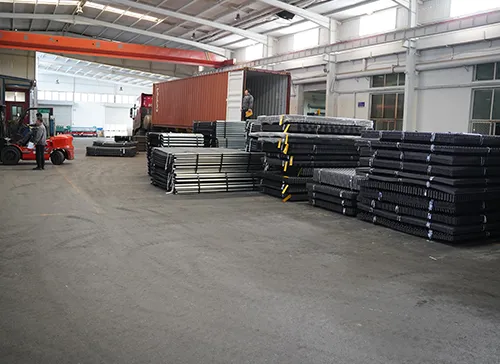

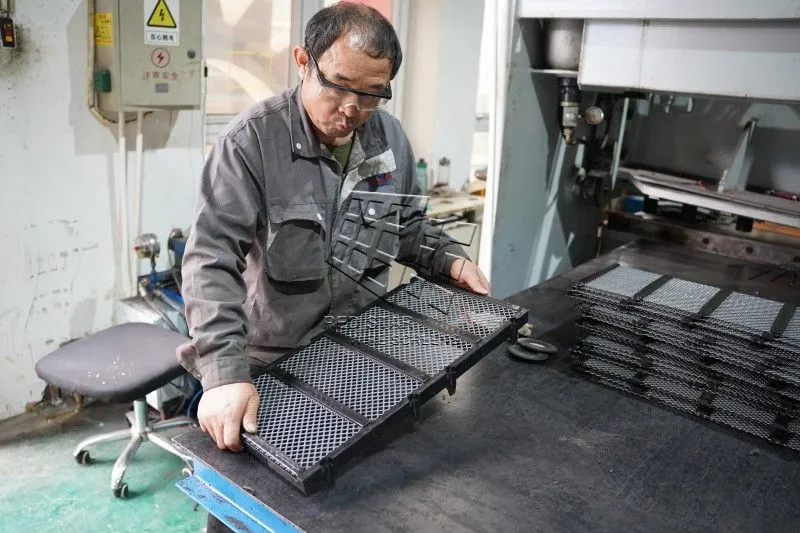

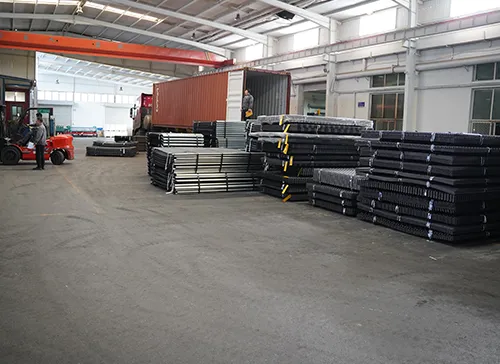

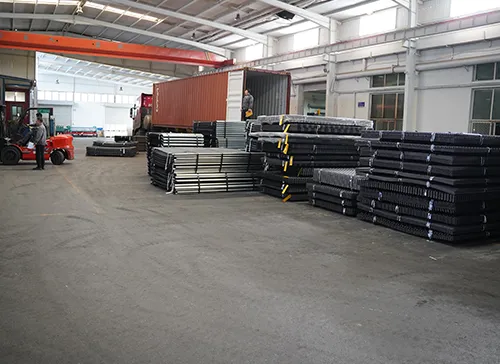

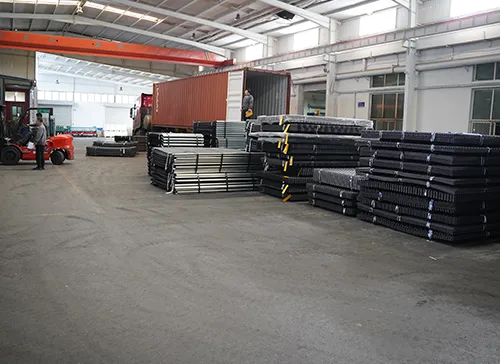

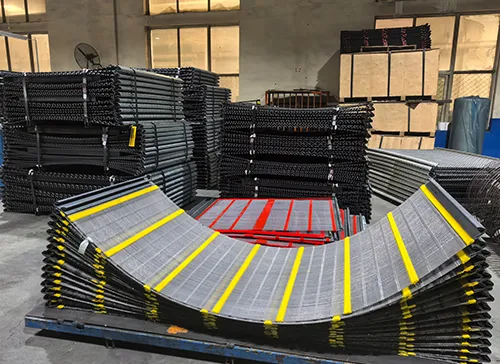

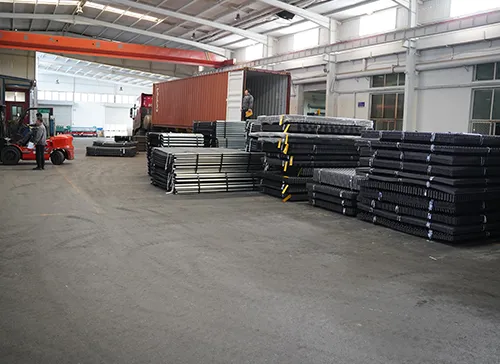

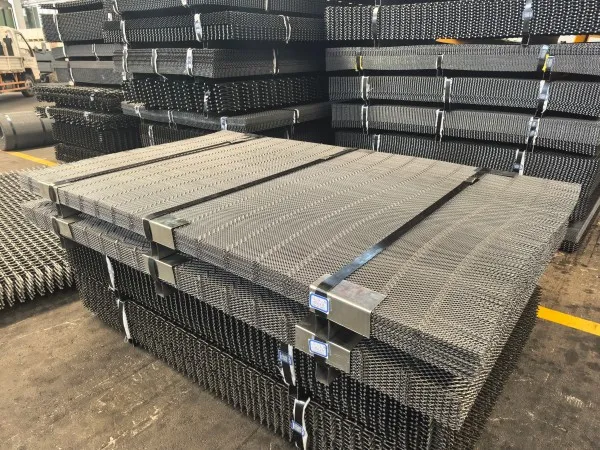

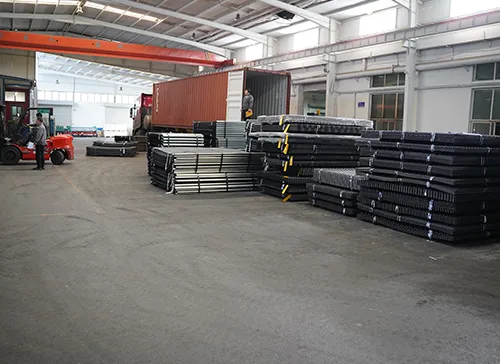

Red Star Wire Mesh Manufacturing Co., Ltd. is a globally recognized supplier with strong technical strength and large-scale production capability in the mining screen mesh industry.

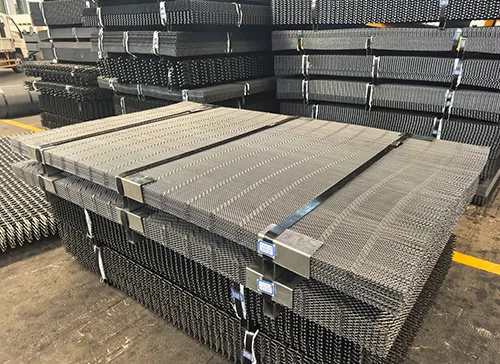

Established in 1989 with 36 years of manufacturing experience

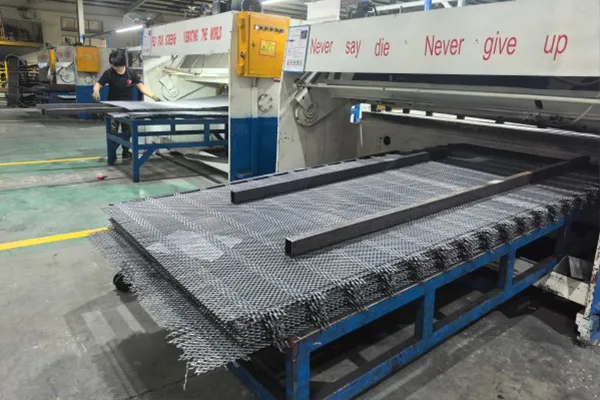

Factory area of 58,730 m² with five specialized production workshops

Over 260 sets of advanced production and testing equipment

Dedicated self-cleaning screen workshop

4000 m² R&D center for new wear-resistant materials

18 patented screening products

Drafting unit for China mining anti-blocking self-cleaning screen standards

ISO9001, ISO14001, ISO45001 certified manufacturer

From raw wire processing to final inspection, every self-cleaning screen panel is manufactured under strict quality control procedures. Advanced wire treatment, precise forming, and comprehensive testing ensure consistent performance in harsh operating environments.

Looking for a dependable Self-Cleaning Screens manufacturer, supplier, or OEM partner? Contact Red Star Wire Mesh today for competitive pricing, technical consultation, and customized screening solutions for your application.

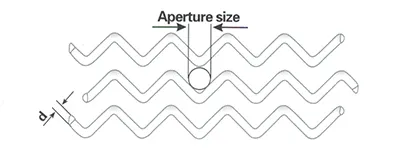

This is the most commonly used self-cleaning screen, highly sought after for its screening accuracy and high aperture ratio.

It adapts well to materials of varying shapes and sizes, accurately screening materials that meet the aperture size.

Material passes through the screen more quickly, preventing accumulation and clogging within the apertures, improving screening efficiency.

It reduces material residue on the screen, enhancing the self-cleaning effect of the screen.

It maintains the screen's optimal shape and performance, resists wear and damage, and reduces the frequency of replacement and maintenance.

Mesh range: 2mm-60mm

Wire diameter range: 1.37mm-9mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

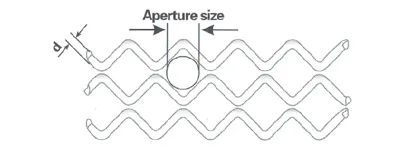

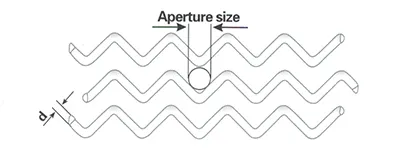

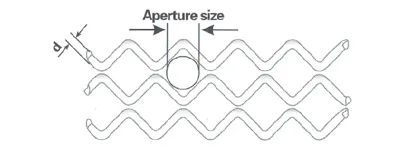

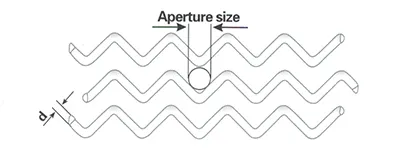

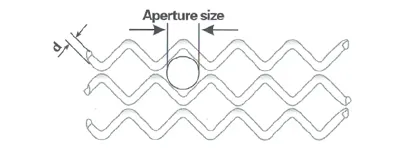

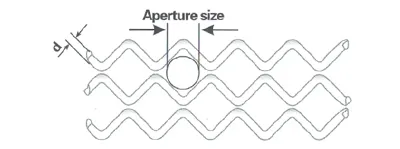

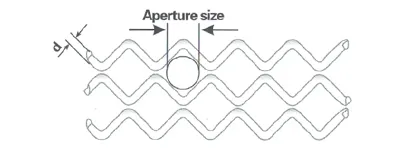

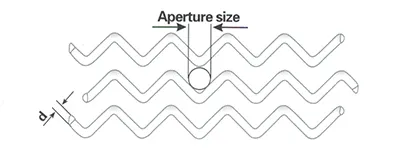

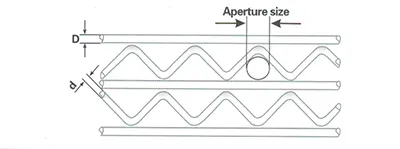

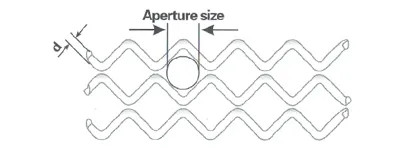

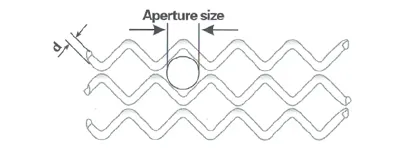

It is especially suitable for screening flakes, long strips and wet materials, with good anti-clogging effect.

Helps the material flow, makes the coarse and fine materials can be better layered, improves the screening precision and efficiency.

Compared with the traditional flat screen, its screening area is larger, the opening ratio is higher, and the material passes through better.

Can withstand greater material impact and vibration load, prolonging the service life of the screen.

Reduce the noise generated by the screen in the process of vibration.

Wire diameter, aperture and material can be adjusted according to customers' requirements, supporting customized products.

Mesh range: 2mm-60mm

Wire diameter range: 1.37mm-9mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

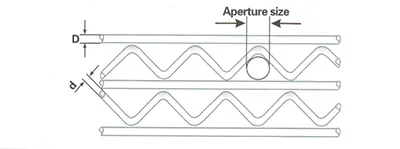

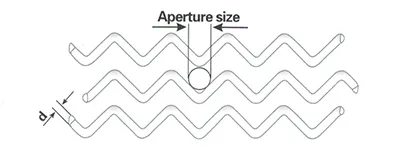

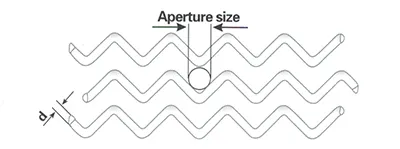

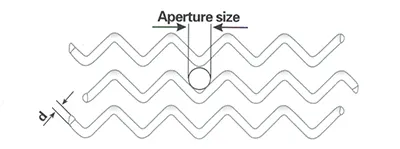

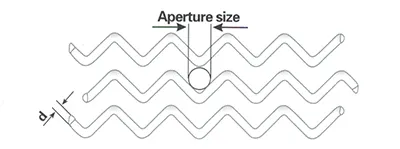

It can accurately classify and screen materials with different particle sizes and improve the screening accuracy.

The edges of the triangular holes are relatively sharp, so the materials cannot easily accumulate and clog in the holes.

The tight fit between the polyurethane pressure bar and the screen prevents the fine materials from escaping from the edge of the screen.

It can withstand greater material impact and vibration load, prolonging the service life of the screen mesh.

During long-term use, it can maintain the shape and performance of the screen mesh, reducing the frequency of replacement and maintenance.

Wire diameter, aperture and material can be adjusted according to customers' requirements, supporting customized products.

Mesh range: 2mm-60mm

Wire diameter range: 1.37mm-9mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type 6-Undulating Profile Screen with PU Frame

Type 1

Type 2

Type 3

Type 4

Type 5

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type 1

Type 2

Type 3

Type 4

Type 5

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

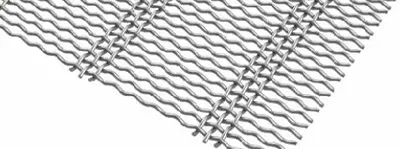

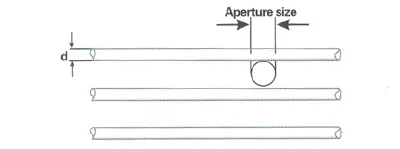

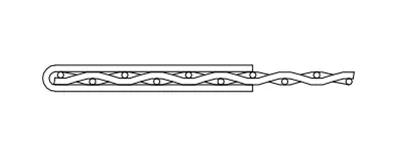

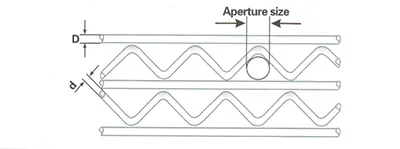

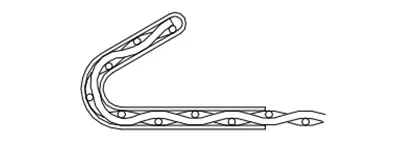

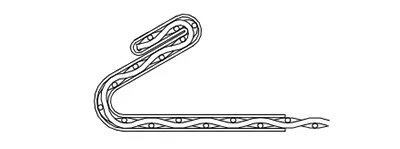

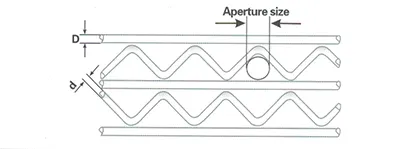

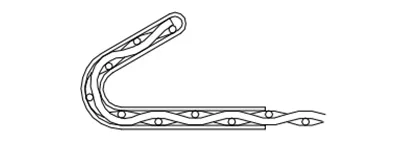

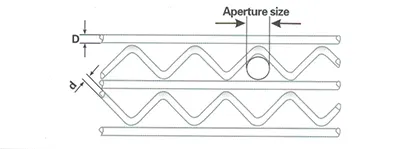

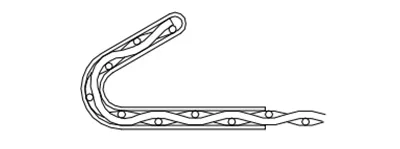

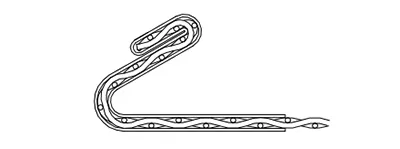

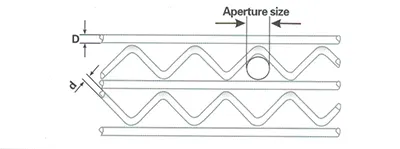

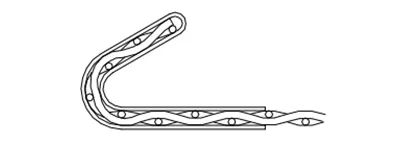

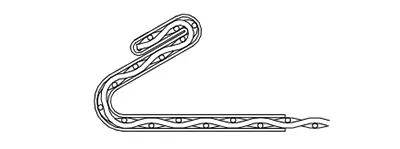

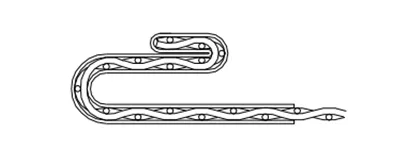

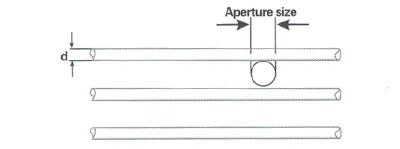

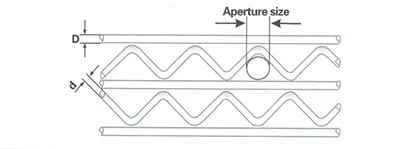

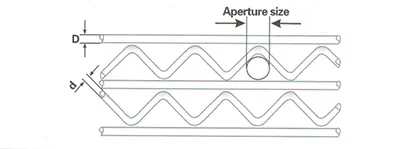

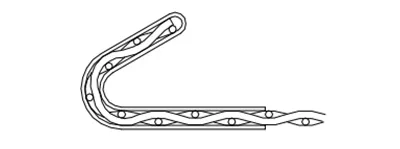

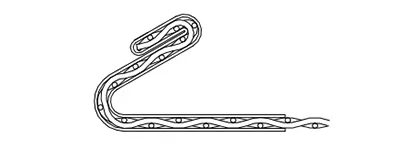

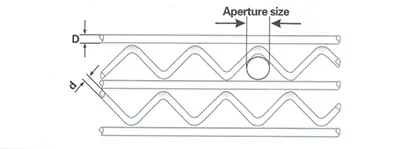

This replaces traditional square-hole woven screens.

The vibrating effect of the screen wires accelerates the material's passage through each layer (reducing the amount of material on the screen surface) and causes the material to "micro-jump," directly impacting the wires rather than sliding and cutting along them.

It is suitable for screening materials with high moisture content, a certain degree of viscosity, and high particle shape requirements, such as stone screening in asphalt pavement on highways.

Screen aperture range: 1.5mm-120mm

Wire diameter range: 0.9mm-12.7mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

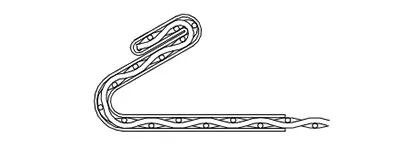

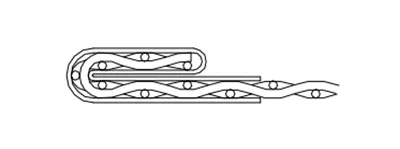

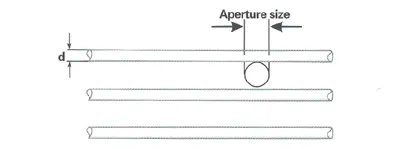

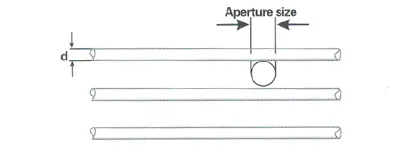

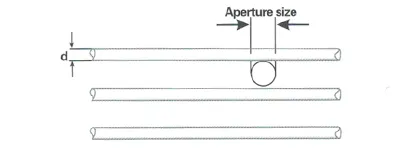

Prevents material from getting stuck in the mesh, which can cause the mesh to become larger and result in irregular screening. This ensures accurate screening and offers greater load-bearing capacity than diamond-shaped anti-clogging screens, while also preventing mesh deformation.

This screen is ideal for small particles, minimizing clogging.

Screen aperture range: 0.5mm to 50.8mm

Screen wire range: 0.6mm to 8mm

Type 1 -Diamond holes with PU support strips

Type 2 -Wave holes with PU support strips

Type 3 -Triangle holes with PU support strips

Type 4- piano wire screen with PU support strips

Type 5- piano wire screen-Removable support bar

Type 1

Type 2

Type 3

Type 4

Type 5

Type A -piano wire screen

Type B -piano wire screen

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Type 7

Type 8

Type 9

Both Hooks Down

Both Hooks Up

One Hook Up and One Hook Down

Our experienced staff is available to discuss your needs and to help determine which product is best for your particular application.

Request a quote or call us at +86 187 3080 2171

Red Star Wire Mesh Manufacturing Co., Ltd. is not an authorized repair facility nor does it have an affiliation with the original equipment manufacturers (OEM) listed above. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval of Red Star Wire Mesh Manufacturing Co., Ltd. , Inc. by the named OEM, respectively. All parts are manufactured by, for and warranted by Red Star Wire Mesh Manufacturing Co., Ltd. are not manufactured by, purchased from or warranted by the OEM.

Factory Address:

1 Hongxing Rd, Anping County, Hengshui, Hebei, China

Email:

info@redstarfactory.com

WhatsApp :

+86 187 3080 2171

Phone:

+86 187 3080 2171

WeChat:

+86 187 3080 2171

Working Hours:

Monday – Friday: 8:00 AM – 5:00 PM (GMT+8). We reply to all inquiries within 12–24 hours, regardless of time zone.